TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 134 of 528

TM 9-2330-356-14

c.

Installation.

(1) Move ring (fig. 3-27) on coupler back toward

hose.

(2)

Install nozzle into coupler and release ring.

(3) Check for proper connection by trying to pull

the nozzle by hand from the hose.

3-16. Closed-Clrcult Nozzle (M970 and M970A1)

a.

Service. The

screen in the nozzle must be cleaned

periodically and whenever flow is restricted through

nozzle.

(1) Remove nozzle (para 3-16).

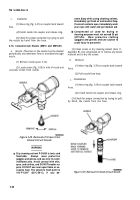

(2) Locate screen (fig. 3-28) in inlet of nozzle and

unscrew screen from nozzle.

come dizzy while using cleaning solvent,

immediately get fresh air and medical help.

If solvent contacts eyes, Immediately wash

your eyes with water and get medical aid.

Compressed air used for drying or

cleaning purposes must not exceed 30 psi

(207 kPa).

Wear protective clothing

(goggles and gloves) and use caution to

avoid injury to personnel.

(3) Clean screen in dry cleaning solvent (item 11,

Appendix E). Use compressed air to remove any excess

material and to dry the screen.

b.

Removal.

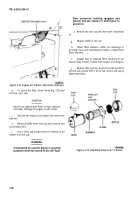

(1) Move ring (fig. 3-29) on coupler back toward

hose.

(2) Pull nozzle from hose.

c.

Installation.

(1) Move ring (fig. 3-29) on coupler back toward

hose.

(2) Install nozzle into coupler and release ring.

(3) Check for proper connection by trying to pull,

by hand, the nozzle from the hose.

Figure 3-28. Removal of Screen From

Closed-Circuit Nozzle.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable.

Always

wear protective

goggles and gloves, and use only In a well-

ventilated area. Avoid contact with skin,

eyes, and clothes, and DO NOT breathe va-

pors. DO NOT use near open flame or ex-

cessive heat. The solvent’s flash point is

100°F-138°F (38°C-59°C). If you be-

Figure 3-29. Removal of Closed-Circuit Nozzle.

3-38

Back to Top