TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 130 of 528

TM 9-2330-356-14

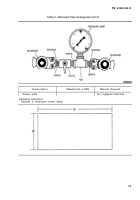

Table 3-2. Operator/Crew Troubleshooting (Con‘t),

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

18. FUEL DOES

Step 3.

19. FUEL DOES

Step 1.

Step 2.

FUELING OPERATIONS (Con’t)

NOT FLOW DURING ANY OVERWING FUELING OPERATION (M970 and M970A1) (Con’t).

Check for clogged screen in nozzle (para 3-1 5).

Clean or replace screen.

NOT FLOW DURING ANY UNDERWING FUELING OPERATION (M970 and M970A1).

Complete Steps 1 through 5 under Malfunction 17,

FUEL DOES NOT FLOW DUR/NG ANY FILTERED

FUELING OPERATION.

Check if deadman actuator was not depressed or is inoperable.

NOTE

Connect towing vehicle to build up air pressure. Deadman will not function without outside air

source.

Step 3.

a.

Depress deadman actuator S to resume flow to meter.

b.

Check deadman hoses for kinks, Straighten kinks.

c.

Check deadman hoses for breaks or loose connections. Notify unit maintenance if any

are found.

Check for clogged screen in nozzle (para 3-17).

Clean or replace screen.

Section IV. MAINTENANCE PROCEDURES

3-5.

General

This section provides maintenance instructions for those

items which are the responsibility of the operator/crew,

The maintenance functions are limited to those

operations that are authorized by the Maintenance

Allocation Chart (MAC), Appendix B of this manual.

3-6.

Batteries, Terminals, and Cables

The battery terminals and cables should be inspected for

excessive dirt and corrosion, loose connections, and

damage each time before the vehicle is put into operation.

Dirt, combined with electrolyte or moisture on top of

battery, can result in a continuous battery discharge.

a.

Inspection Steps and Services.

(1) Remove the two wingnuts and washers

(fig. 3-22) that secure the battery cover to the battery hold

down bracket. Remove the battery cover.

(2) Inspect battery area for excessive dirt and

corrosion. Clean battery area using instructions in

b

below.

3-34

Back to Top