TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 210 of 528

TM 9-2330-356-14

(5) Look for damaged brake camshaft.

(6) Look for worn brake hoses or damaged broke

chamber.

(7) Check tightness of bobs which fasten bogie

assembly to trailer frame.

c.

Repair.

Tighten loose bolts. If damage or wear is

evident, notify direct support maintenance.

4-30. Spring Seat Bearings, M967, M969, M970 except

M970 SN TC-0843, TC-0844, and TC-103 thru TC-178.

a. Lubrication Internal. See

figures 3-1 through 3-6,

Lubrication Chart.

b.

Procedure.

Remove plug A on bottom of spring

seat (fig. 3-7) and install a ¼-inch NPT grease fitting.

Apply enough grease to ensure lubrication of the

bearings. Remove grease fitting and install plug.

c.

Replacement of Bearings.

If excessive wear is

evident in the spring seat bearings, notify direct support

maintenance.

Section XII. MAINTENANCE OF BRAKE SYSTEM

4-31.

General, M967, M969, and M970 except M970

SN TC-0843, TC-0844, and TC-103 thru TC-178.

a.

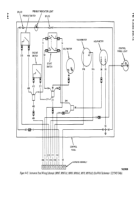

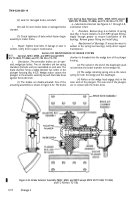

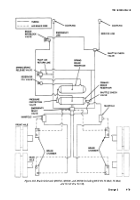

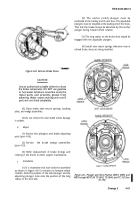

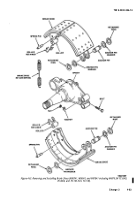

Description. The

semitrailer brakes are air-oper-

ated, wedge-type brakes. Two air chambers and two spring

chambers (fail-safe unit) are assembled on each axle. The

brake chamber forces a wedge between two rollers in the

plunger housing (fig. 4-52). Wedge action causes the

plungers in the actuator assembly to push the brake shoes

against the brake drum.

(1) The brakes are double-actuated. One of the

actuating assemblies is shown in figure 4-52. The brake

chamber is threaded into the wedge bore of the plunger

housing.

(2) The socket in the end of the diaphragm push

rod connects the brake chamber to the wedge rod.

(3) The wedge retracting spring acts as the return

spring for both the wedge and the diaphragm.

(4) Rollers on the wedge head engage slots in the

inner ends of the plungers. The outer end of the plungers

are in contact with the brake shoes.

Figure 4-52. Brake Actuator Assembly (M967, M969, and M970 except M970 SN TC-0843, TC-0844,

and TC-103 thru TC-178).

4-74

Change 3

Back to Top