TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 201 of 528

TM 9-2330-356-14

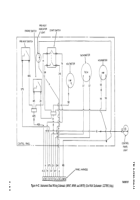

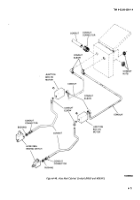

c.

Replacement of Preheat indicator Light.

Refer to

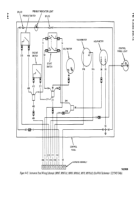

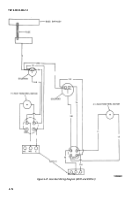

figures 4-39 and 4-41, and engine control panel schematic

figures 4-42 and 4-43 as guides for replacement of

indicator light.

(1)

Removal.

(a)

Disconnect negative battery lead from

battery (para 4-23).

(b)

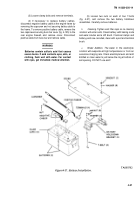

Remove six screws (fig. 4-39) securing

control panel door and pull door open. Hold door ata90°

angle with control panel with a 20-inch length of safety

wire threaded through one hole in door and

corresponding hole in control panel.

(c) Separate indicator light socket

(fig. 4-39) from light body by pulling on socket.

(d)

Remove nut and washer securing light

body to control panel door. Remove light body.

(e)

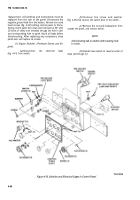

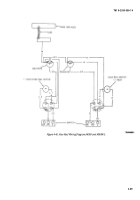

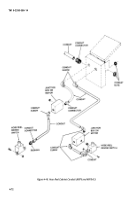

Remove crimp splices (fig. 4-41) on the

indicator light ground leads. Disconnect the other lead

from control panel harness.

(f)

Remove indicator light socket.

(2)

Installation.

(a)

Insert light body (fig. 4-39) through hole

in door and secure with washer and nut.

(b)

Insert socket into light body.

(c)

Connect the light ground lead (fig. 4-41)

to the existing wire using a crimp splice. Install remaining

wire by crimping splice to control panel harness.

(d)

Remove safety wire from control panel

door and close door. Be sure that tubing to gages is not

folded or crimped. Secure door with six screws.

(e)

Install battery negative ground lead

(para 4-23).

d.

Preheat Indicator Light Lamp Replacement.

(1) Remove six screws (fig. 4-39) securing

control panel door and pull door open.

(2) Separate indicator light socket from light

body.

(3) Remove lamp from the indicator socket and

install a new lamp.

(4) Replace indicator light socket into light body.

(5) Close panel door. Be sure that tubing to gages

is not folded or crimped. Secure door with six screws.

e.

Replacement of Control Panel Plate.

Remove all

switches, gages and light following instructions in

b

and

c

above. Remove four capscrews (fig. 4-39) which fasten

plate to control panel. Remove control panel plate. Install

new plate and reinstall switches, gages, and light.

f.

Repair of Wiring.

Repair any cracked, cut, or

broken insulation with electrical tape (item 29, Appendix

E). Replace wiring when damage cannot be repaired.

Tighten loose connections.

4-25. Control Panel Wiring Harness and Conduit

WARNING

When troubleshooting an electrical malfunc-

tion or performing electrical maintenance,

ALWAYS disconnect intervehicular electrical

cable from semitrailer, and negative battery

cables at batteries. Failure to follow this warn-

ing may create a spark and explosion, result-

ing In serious injury or death to personnel.

a.

Repair of Wiring.

Repair any cracked, cut, or

broken insulation with electrical tape (item 29, Appendix

E). Replace wiring harness when damage cannot

repaired.

b.

Replacement of Control Panel Wiring Harness.

(1)

Removal.

(a)

Open control panel by removing

be

six

round head screws (fig. 4-39) and swinging panel down.

(b)

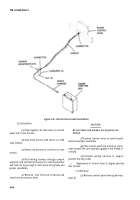

Disconnect all electrical leads and

jumper assemblies from control panel wiring harness

(fig. 4-41).

(c)

With a wire cutter, remove all terminals

from the ends of the harness wires.

(d)

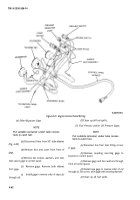

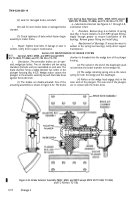

Disconnect the wiring harness from the

engine junction box (fig. 4-44).

(e)

Secure a strong cord, about ten feet

longer than the harness, to the end of the wiring harness.

(f)

Pull harness out of conduit and allow

cord to be pulled into the conduit. When harness is out,

cord should be visible at both ends of conduit.

4-65

Back to Top