TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 240 of 528

TM 9-2330-356-14

c.

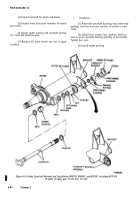

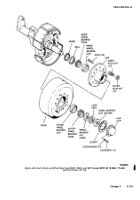

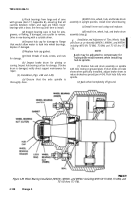

Replacement of Wheel Bearings (M967, M969, and

M970 except M970 SN TC-0843, TC-0844, and TC-103 thru

TC-178) (F{g. 4-86).

(1) Removal.

(a)

Remove tires, wheels hub and drum as

an assembly

(b

above).

(b)

Remove wiper (fig. 4-86) from either the

hub or the axle spindle.

NOTE

If no seal puller is available, drive bearing

cone

and seal out using a brass drift and

hammer from the outer side of the hub.

(c)

Remove inner seal with a seal puller and

then remove inner wheel bearing cone.

(2)

Inspection and Repair.

WARNING

Dry cleaning solvent P-D-680

Is

toxic and

flammable.

Always wear protective

goggles and gloves, and use only In a well-

ventilated area. Avoid contact with skin,

eyes, and clothes, and DO NOT breathe va-

pors. DO NOT use near open flame or ex-

cessive heat. The solvent’s flash point is

100°F-138°F (38°C-59°C). If you be-

come dizzy while using cleaning solvent,

Immediately get fresh air and medical help.

If solvent contacts eyes, Immediately wash

your eyes with water and get medical aid.

Compressed air used for drying or clean-

ing purposes must not exceed 30 psi

(207 kPa).

Wear protective clothing

(goggles and gloves) and use caution to

avoid injury to personnel.

CAUTION

Do not clean parts with gasoline, In a hot

solution tank, or with water and alkaline

solutions. Separate wheels and hub before

cleaning.

Dry cleaning solvent will

deteriorate the tires.

Do not spin bearings with compressed air.

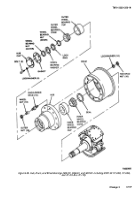

(u)

Thoroughly clean all parts with dry

cleaning solvent (item 11. Appendix E) and a stiff fiber

brush. Ensure that parts are completely dry. Use low

pressure compressed air to dry parts, if available.

NOTE

If wheel bearings need replacing, bearing

cups must also be replaced (Step

(d)).

(b)

Inspect wheel bearings for cracks or

breaks in bearing cage, etching or pitting on roller

surfaces, and any evidence of wear. Replace if worn or

damaged.

(c)

Pack bearings from large end of cone

with grease (item 17, Appendix E), ensuring that ail

cavities between rollers and cage are filled. Cover

bearings with a clean, lint-free rag until time to install.

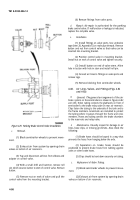

(d)

Inspect bearing cups in hub for pits,

grooves, or flaking. If damaged, use a puller to remove.

Drive in new bearing cups with a suitable driver.

(e)

Inspect hub cap for damage to flange

that would allow water to leak into wheel bearings.

Replace if damaged.

(f)

Replace hub cap gasket.

(g)

Cheek threads of studs, screws, and nuts

for damage.

(h)

Inspect brake drum for pitting or

scoring. Inspect hub bearing surface for damage. If brake

drum is damaged, notify direct support maintenance for

repair.

(3)

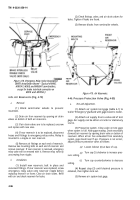

Installation (Figs. 4-86 and 4-87).

(a)

Ensure that the axle spindle is

thoroughly clean.

(b)

Install inner seal and wiper using seal

replacer.

(c)

With tire, wheel, hub. and brake drum

assembly in upright position, install inner wheel bearing.

(d)

Install tire, wheel, hub, and brake drum

assembly

(d

below).

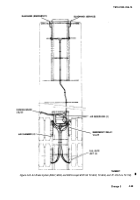

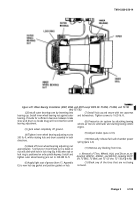

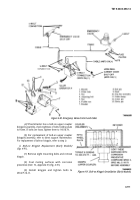

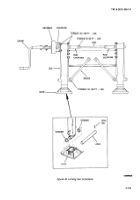

d.

Installation and Adjustment of Tires, Wheels, Hub,

and Drum as an Assembly (M967, M969, and M970 except

M970 SN TC-0843, TC-0844, and TC-103 thru TC-178).

NOTE

Jack may be adjusted to compensate for

hub/spindle misalinement when installing

hub to spindle.

(1) Position hub and drum assembly on spindle

with tires resting on greased plate. If drum binds on brake

shoes when partially installed, turn both adjusting bolt

starwheels to reduce brake shoe spread (para 4-33). Push

hubs fully onto spindle.

4-104

Change 3

Back to Top