TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 246 of 528

TM 9-2330-356-14

b.

Inspection.

Remove objects such as nails or glass.

c.

Repair.

Refer to TM 9-2610-200-24 for

Check for apparent loss of air, unusual wear, or missing

instructions on dismounting, repair, and mounting of tire

valve caps. Replace as required.

and tube on rim.

Section XIV. MAINTENANCE OF FRAME AND TOWING

4-51.

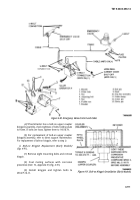

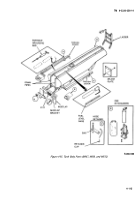

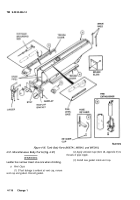

Emergency Valve Control and Cable

(Fig. 4-90)

a.

Cleaning and Inspection.

WARNING

Dry cleaning solvent P-D-680 Is toxic and

flammable. Always wear protective goggles

and gloves, and use only In a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while us-

ing cleaning solvent, Immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

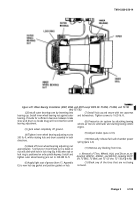

(1) Clean control handle of valve operator A and

connecting parts, cable and emergency valve with dry

cleaning solvent (item 11, Appendix E).

(2) Inspect for cracks in control handle, frayed

cables, loose U-bolts, loose or bent cable runways, cotter

pins, and control mounting bolts.

b.

Service.

(1) Tighten any loose U-bolt c-able connectors,

adjusting bolts, and bracket mounting bolts at each end of

cable. Adjust if necessary.

(2) Lubricate all linkage.

c.

Adjustment.

(1) Ensure that control handle of valve operator

A is pushed in and that the emergency valve is closed. Pull

on handle of the emergency valve shutoff at front curbside

of semitrailer to maintain shutoff handle in the open

position.

(2) Loosen U-bolt connectors to loosen cable

end connections.

(3) Remove all slack in cables, then tighten

U-bolt connectors.

(4) Cheek

ATTACHMENTS

that emergency valve will open and

close when control handle of valve operator A is operated.

(5) Pull on valve operator A to open emergency

valve. Check that pulling on the emergency valve shut-off

handle will close the emergency valve.

(6) Repeat steps (1) through (5) if cables do not

function properly.

d.

Removal. Tag

and disconnect control cables from

the emergency valve control. Remove two capscrews and

nuts that secure control to side of cabinet. Remove valve

control.

e.

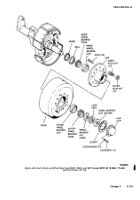

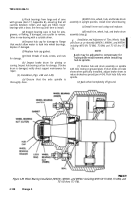

Disassembly and Assembly (Fig.

4-90).

(1) Remove roll pin (8, fig. 4-90) securing shaft

(9) to bracket (7).

(2) Remove shaft (9). Remove lever (1) and the

trip bar assembly (10).

(3) Remove cotter pin (12) and clevis pin (13) that

secures offset link (2) to handle(l). Remove offset link(2).

(4) Disassemble further if needed (fig. 4-90).

(5) Reassemble by reversing steps (1) through

(4).

f.

Installation.

(1) Mount emergency valve control in place

using two nuts and capserews.

(2) Reconnect the cables and adjust (step c).

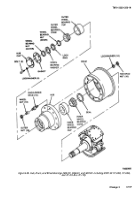

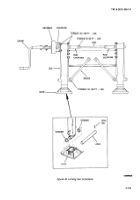

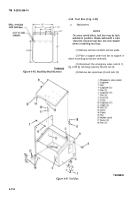

4-52. Upper Coupler/Kingpin Assembly

a.

Service.

(1)

Remove dust, dirt, and old grease from

kingpin.

(2) Grease liberally with clean grease (item 17,

Appendix E).

(3) If semitrailer has a bolt-on kingpin, check

tightness of bolts holding kingpin to plate (fig. 4-91).

4-110

Back to Top