TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 245 of 528

TM 9-2330-356-14

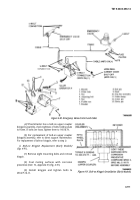

(3) Tighten inner adjustment nut to minimum of 75 ft-

lb to ensure proper seating of e bearings and cup in wheel hub.

(4) Loosen inner adjustment nut so wheel will turn

freely.

(5) Retighten inner adjustment nut to 50 ft-lb while

rotating wheel, in order to properly position bearings for final

adjustment.

(6) Looscn inner adjustment nut 1/3 turn.

WARNING

Failure to beck off the inner adjustment nut could

cause bring and axle spindle overheating or dam-

age,.which could result m the wheel Iocking up or

coming off during vehicle operation, resulting in

property damage or loss of life.

(7) Install spindle nut lockwasher so that dowel on inner

nut alines with hole in lockwasher and washer tang tits in spindle

keyway.

WARNING

Failure to torque outer locknut properly could

cause wheel to come off during vehicle operation,

which could result m property damage or loss of life.

If an external tan or setscrew-type lockwaaher

is used, it is important to remember to bend tabs over

outer locknut, or to install the setscrew in lockwasher,

after the outer nut has been properly torqued.

(8) Install outer locknut and tighten to 250-400 ft-lb.

(9) Apply a light coat of grease (Item 17, Appendix E)

to new hub cap gas et and position gasket on hub.

(10) Install hub cap and secure with six bolts and

lockwashers. Tighten bolts to 16-20 ft.-lb.

(11) Pressurize air system by attaching towing vehicle

air lines to semitrailer and starting towing vehicle engine.

(12)

(13)

(para 2-4).

(14)

Adjust brakes (para 4-34).

Manually release fail-safe chamber power spring

Remove any blocking from tires.

h.

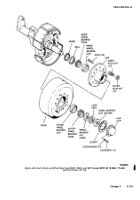

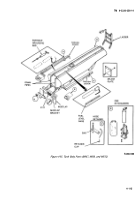

Wheel Studs (M967, M969, and M970 except M970 SN

TC-0843, TC-0844, and TC-103 thru TC-178).

(1) Removal (Fig. 4-86).

(a) Remove tire and wheel.

(b) Remove five screws that fasten brake drum to

hub and remove brake drum.

(c Remove ten capscrews that fasten hub cap to

hub. Remove hub cap and gasket.

(d) Using wheel bearing nut wrench, remove outer

wheel bearing nut, lock ring, and inner wheel bearing nut.

(e) Remove outer wheel bearing cone.

(f) Remove hub from axle spindle being careful

not to damage wiper and seal.

(g) l)rive broken wheel studs from hub.

(2)

Installation (Fig. 4-86).

(a) Install wheel studs into hub. Use a hammer and

driver to install studs.

(b) If wiper remained with axle spindle when hub

was removed, remove roper and install in hub. Install outer wheel

bearing cone in hub.

(c) Pack bearings from large end of cone

with grease (item 17, Appendix E) making sure all cavities

between rollers and cup are filled.

(d) Install hub onto axle spindle. Install

inner wheel bearing nut, lock ring, and outer wheel

bearing nut, but do not tighten.

(e) Install brake drum over the hub and

secure with five screws.

(f) Install wheels and adjust wheel bearings.

i

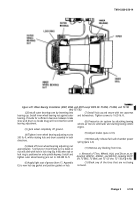

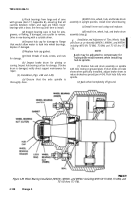

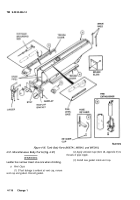

Wheel Studs (M967A1, M969A1, and M970A1

including M970 SN TC-0843, TC-0844, and TC-103

thru TC-178).

(1)

Removal (Fig. 4-88).

(a)

Remove wheels and tires.

(b)

Remove six bolts and lockwashers that

fasten the hub cap to the hub. Remove hubcap and gasket.

(c)

Using wheel bearing nut wrench remove

outer wheel bearing nut, wheel bearing washer, lock ring,

and inner wheel bearing nut.

(d)

Remove outer wheel bearing crone.

(e)

Remove hub and drum from axle spindle

being careful not to damage seal.

(f)

Remove nuts, lockwashers, and broken

studs from hub and drum.

(2) Installation (Fig. 4-88).

(a)

Install studs (short side from shoulder

facing out) into hub and drum and secure studs with

lockwashers and nuts.

(b)

Install hub and drum onto axle spindle.

(c) Pack bearing from large end of cone with

grease (item 17, Appendix E) making sure all cavities

between rollers and cup are filled.

(d)

Install outer wheel bearing cone in hub.

(e)

Install inner bearing nut, lock ring,

wheel bearing washer, and outer wheel bearing nut, but do

not tighten.

(f)

Install wheels and tires and adjust wheel

bearings.

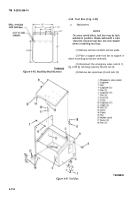

4-50. Tire and Tube

a

Service. Gage tires for correct pressure. For hard

surface roads, inflate to 60 psi; for cross-country and sand,

inflate to 40 psi.

Change 3

4-109

Back to Top