TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 244 of 528

TM 9-2330-356-14

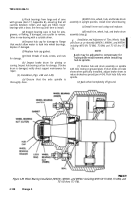

(c)

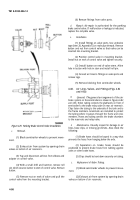

Pack bearings from large end of cone

with grease (item 17, Appendix E), ensuring that all

cavities between rollers and cage are filled. Cover

bearings with a clean, lint-free rag until time to install.

(d)

Inspect bearing cups in hub for pits,

grooves, or flaking. If damaged, use a puller to remove.

Drive in new bearing with a suitable driver.

(e)

Inspect hub cap for damage to flange

that would allow water to leak into wheel bearings.

Replace if damaged.

(f)

Replace hub cap gasket.

(g)

Check threads of studs, screws, and nuts

for damage.

(h) Inspect

brake drum for pitting or

scoring. Inspect hub bearing surface for damage. If brake

drum is damaged, notify direct support maintenance for

repair,

(3)

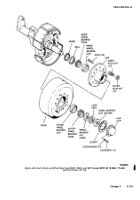

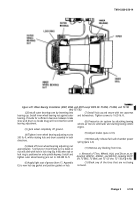

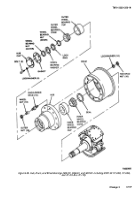

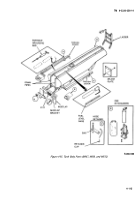

Installation (Figs. 4-88 and 4-89).

(a)

Ensure that the axle spindle is

thoroughly clean.

(b)

With tire, wheel, hub, and brake drum

assembly in upright position, install inner wheel bearing

:

(c)

Install inner seal using seal replacer.

(d)

Install tire, wheel, hub, and brake drum

assembly (step g).

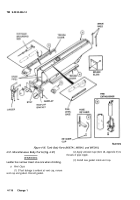

g.

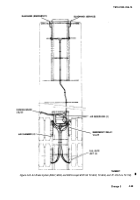

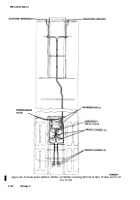

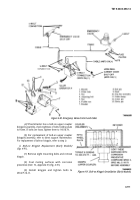

Installation and Adjustment of Tires, Wheels, Hubs,

and Drum as an Assembly (M967A1, M969A1, and M970A1

including M970 SN TC-0843, TC-0844, and TC-103 thru TC-

178).

NOTE

Jack may bc adjusted to compensate for

hub/spindle misalinement when installing

hub to spindle.

(1) Position hub and drum assembly on spindle

with tires resting on greased plate. If drum binds on brake

shoes when partially installed, adjust brake shoes to

reduce brakeshoe spread (para 4-34). Push hubs fully onto

spindle.

(2) Jack wheel completely off ground.

Figure 4-89. Wheel Bearing Installation (M967A1, M969A1, and M970A1 including M970 SN TC-0843, TC-0844, and

TC-103 thru TC-178).

4-108

Change 3

Back to Top