TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 237 of 528

TM 9-2330-356-14

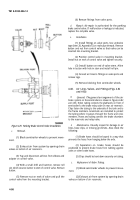

(3) Disconnect tubing from fitting and remove

the insert, compression sleeve and nut on both ends of

tubing. Release the clips and pull tubing through

grommets.

NOTE

Tubing is stocked in bulk lengths. Measure

original tubing and cut new tubing to same

length.

(4) Install tubing on semitrailer and bend clips

down securely to hold tubing in position.

Section XIII.

4-49. Wheels, Hubs, and Drums

WARNING

Spare tire vveighs 190 pounds. Four-person

lift, or suitable lifting device, is required.

(5) Trim ends of tubing to get a smooth, square

cut. Slide tubing nut on end of tube. Slide impression

sleeve over end oft tubing. Install tubing insert. Connect

tubing to adapter fitting and tighten tubing nut securely.

Do the same procedure on both ends.

(6) Check replaced tubing for leaks. No leaks are

permitted.

(7) Remove blocking from semitrailer wheels.

d. Air Line Fittings.

Use antiseize tape (item 28,

Appendix E) on all male pipe threads. Take care not to let

any of the tape get into the system.

MAINTENANCE OF WHEELS, HUBS, AND DRUMS

a

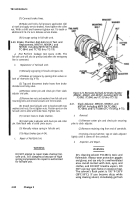

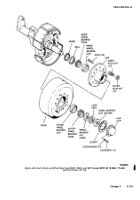

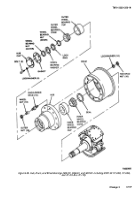

Tire and Wheel Replacement (Fig. 4-84).

(1)

Removal.

Bbck any of the tires that are not

being removed. Jack up axle until tire is clear of ground.

Support axle with jack stand or blocking. Remove outer

stud nuts (fig. 4-84). Remove tire and wheel assembly. If

inner tire must be removed, remove the ten inner stud

nuts (fig. 4-84), and remove inner tire and wheel assembly.

(2) Repair.

(a)

Repair tubes (para 4-50).

(b)

Refer to general support maintenance

for repair of tires.

(3)

Installation.

Position inner wheel over studs

on axle hub. Replace ten inner stud nuts (fig. 4-84), lower

tire to ground, and tighten to 450-500 lb.-ft. using

sequence in figure 4-85. Jack up rude and position outer

wheel over inner stud nuts (fig. 4-84). Lower tire to

ground, and using sequence in figure 4-85, tighten nuts to

450-500 lb.-ft.

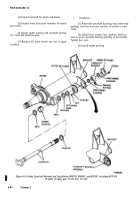

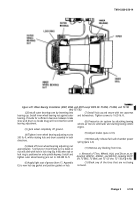

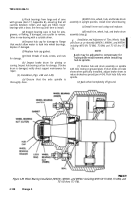

b. Removal of Tires, Wheels, Hub, and Drum as an

Assembly (M967, M969, and M970 except M970 SN

TC-0843, TC-0844, and TC-103 thru TC-178) (Fig. 4-86).

WARNING

The fall-safe chamber power spring must be

manually compressed and the air reservoirs

must be vented of pressure before removal of

hub and drum assembly.

(2) Manually compress fail-safe chamber power

spring (para 2-4).

(3) Release air pressure by opening drain wolves

on both air reservoirs (fig. 4-79).

(4) Jack up axle until tires are clear of ground.

Support rude with jack stand or blocking.

(5) Remove ten screws and lockwashers

(fig. 4-86) securing hub cap to hub. Remove hub cap and

hub cap gasket. Discard gasket.

(6) Remove outer wheel bearing nut (fig. 4-86),

leek ring, and inns wheel bring nut.

(7) Remove outer wheel bearing cone.

NOTE

If wheel lift jack is not available follow steps

(8) through (10).

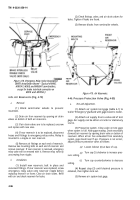

(8) Apply grease (item 17, Appendix E) to a

45x20-inch 10 gage steel plate (table 4-1), laying a grease

track approximately lo-inches wide the length of the

plate.

(9) Place the grease plate, with greased side up,

under the tires. Lower tires so that they are just resting on

the grease plate, with the majority of the vehicle weight

still on the jack.

NOTE

It maybe necessary to back the automatic

adjusters out to allow brake shoes to dear

ridge on brake drum (para 4-33).

(10) Wide tires, wheels, hub, and brake drum off of

axle spindle.

(1) Block any of the tires that are not being

removed.

Change 3

4-101

Back to Top