TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 229 of 528

TM 9-2330-356-14

air and medical help. If solvent contacts eyes,

Immediately wash your eyes with water and

get medical aid.

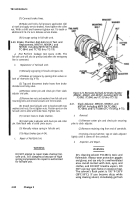

(1) Thoroughly clean slack adjuster, splines of

camshaft, and other metal parts using dry cleaning solvent

(item 11, Appendix E) and a stiff fiber brush. Make sure

parts are completely dry.

(2) Inspect slack adjuster for external damage,

and the worm shaft hex head for being frozen or binding.

(3) Replace all parts which are not in good

condition.

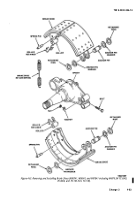

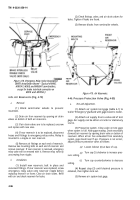

Figure 4-75. Removing and Installing Slack Adjuster

(M967A1, M969A1, and M970A1 including M970 SN

TC-0843, TC-0844, and TC-103 thru C-178).

c.

Installation.

(1) Place slack adjuster into position on cam-

shaft. Use a brass hammer to lightly tap it into place.

(2) Install retaining ring into recess on camshaft.

(3) Place yoke into position at slack adjuster and

install clevis pin.

(4) Install

cotter pin to secure clevis pin.

(5) Adjust slack adjuster (para 4-34).

(6) Lubricate slack adjuster (fig. 3-16).

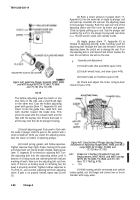

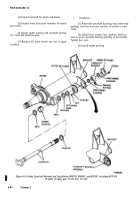

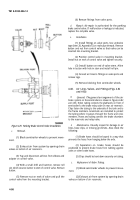

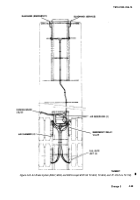

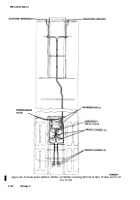

4-42. Brake Camshaft, M967A1, M969A1, and

M970A1 including M970 SN TC-0843,

TC-0844, andTC-103 thru TC-178 (Fig. 4-76).

a .

Removal.

(1) Remove wheel and drum assembly

(para 4-49).

(2) Remove brake shoes (para 4-34).

(3) Remove slack adjuster (para 4-41).

(4) Expand retaining ring and slide camshaft part

way out of spider. Remove retaining ring.

(5) Slide camshaft out of spider.

(6) Remove two washers and two seals from

camshaft.

(7) Remove spider bushing.

(8) Remove four nuts, four washers, and four

screws securing camshaft bushing assembly to bracket.

(9) Remove inner retainer and outer retainer.

(10) Remove camshaft bushing and two

preformed packings.

b.

Inspection and Repair.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable.

Always wear protective

goggles and gloves, and use only in a

well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT

breathe vapors. DO NOT use near open

flame or excessive heat. The solvent’s

flash point Is 100°F-138°F (38°C-59°C).

If you become dizzy while using cleaning

solvent, Immediately get fresh air and

medical help. If solvent contacts eyes,

Immediately wash your eyes with water

and get medical aid.

Compressed air used for drying or

cleaning purposes must not exceed 30 psi

(207 kPa).

Wear protective clothing

(goggles and gloves) and use caution to

avoid Injury to personnel.

NOTE

Use a wire brush to clean camshaft and Inner

and outer retainers, If required, to remove

caked-on dirt and corrosion.

(1) Thoroughly clean all metal parts with dry

cleaning solvent (item 11, Appendix E). Dry the parts with

low pressure compressed air.

Change 3

4-93

Back to Top