TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 224 of 528

TM 9-2330-356-14

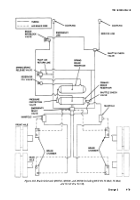

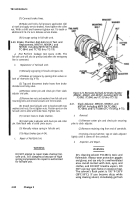

Figure 4-68, Adjusting Plunger Assembly (M967, M969,

and M970 except M970 SN TC-0843, TC-0844,

and TC-103 thru TC-178).

NOTE

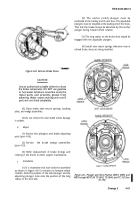

The hollow adjusting pawl has teeth on one

end, flats on the side, and a chamfered edge

on the other end. Coat the hollow adjusting

pawl with grease (Item 17, Appendix E) and

Insert it into the guide hole, teeth first, and

with chamfer toward the brake shoe. This

alines the pawl with the actuator teeth and the

flats with the keyway slot. Ensure that pawl is

all the way into the slot In plunger housing.

(3) Install adjusting pawl. Push pawl in flush with

the inside of plunger. Hold the pawl in this position with a

smaIl screwdriver while you install the adjusting sleeve,

Seat the sleeve on bottom of adjusting plunger.

(4) Install spring, gasket, and hollow capscrew.

Tighten capscrew finger tight. Proper meshing of the pawl

and sleeve teeth can now be double checked. Apply grease

(item 17, Appendix E) to threads on adjusting bolt. Turn

the adjusting bolt into the adjusting sleeve until it

bottoms. A clicking sound and ratcheting feel will indicate

meshing of teeth. Now turn the adjusting bolt out three

turns. If there is no clicking sound or ratcheting feel, the

paw] is properly meshed, Tighten hollow capscrew to

15-20 lb.-ft., and unscrew adjusting bolt from adjusting

sleeve. If pawl is not properly meshed, repeat steps (2) and

(3).

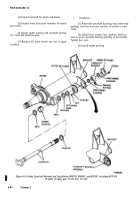

(5) Pack a small amount of grease (item 17,

Appendix E) into the underside of single lip plunger seal

and seal lips. Assemble the seal over the adjusting sleeve

in the plunger housing. Push the seal over end of the

adjusting sleeve until the inner lip enters seal groove.

Check by lightly pulling up on seal. Seat the plunger seal

assembly (fig. 4-67) in the plunger housing with seal driver

or a 1¾-inch wrench socket and rawhide mallet.

(6) Apply grease (item 17, Appendix E) to

threads of adjusting bolt (fig. 4-66). Carefully push the

adjusting bolt through the seal and thread it into the

adjusting sleeve. Be careful not to damage the seal. Turn

the adjusting bolt in until head of bolt almost touches the

seal. Do not bottom the bolt on the seal.

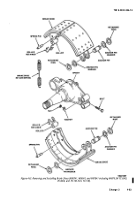

g.

Assembly and Adjustment.

(1) Install brake shoe assemblies (para 4-33).

(2) Install wheels hubs, and drum (para 4-49).

(3) Install brake air chambers (para 4-39).

(4) Check and adjust the

clearance (para 4-33).

brake lining-to-drum

Figure 4-69. Cross-Section of Plunger Housing Showing

Installation of Adjusting Plunger (M967, M969, and M970

except M970 SN TC-0843, TC-0844, and

TC-103 thru TC-178).

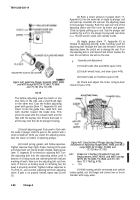

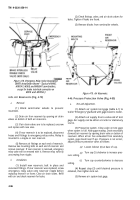

4-37.

Brake Air Chamber (Standard) Test and

Replacement, M967, M969, and M970 except

M970 SN TC-0843, TC-0844, and TC-103

thru TC-178 (Fig. 4-70).

a.

Test.

(1) With towing vehicle connected and vehicle

brakes applied, coat the flanges and connect ions on the air

chamber with soapy water.

4-88

Change 3

Back to Top