TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 226 of 528

TM 9-2330-356-14

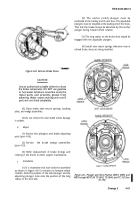

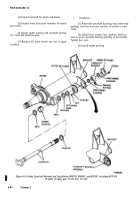

Figure 4-71. Removing and Installing Brake Chamber

(M967A1, M969A1, and M970A1 including M970 SN

TC-0843, TC-0844, and TC-103 thru TC-178).

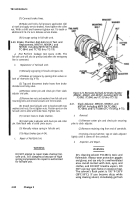

CAUTION

DO NOT overtighten clamp on air chamber.

Maximum torque should be 20-25 lb.-ft.

Over-tightening will distort the flange and

cause more leakage.

(3) If leakage is found at flange, tighten the

clamp. If leakage is found at connection% tighten fittings.

(4) After initial brake application forces out a

small amount of air, no air should be expelled from the air

chamber. If air continues to exhaust, replacement of the air

chamber is necessary.

b.

Removal.

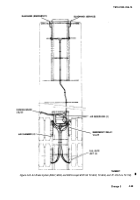

(1) Open drain valves on the air reservoirs and

allow air to bleed off (fig. 4-79).

(2) Disconnect two brake hoses from brake

chamber (fig. 4-71).

(3) Remove cotter pin and clevis pin securing

yoke to slack adjuster.

(4) Remove two nuts and two washers securing

brake chamber to bracket.

(5) Remove brake chamber.

c .

Repair. No

repair of brake chamber is authorized.

d.

Installation.

(1) Place brake chamber in position on bracket

(fig. 4-71).

(2) Install two washers and two nuts to secure

brake chamber to bracket.

(3) Check yoke adjustment (para 4-34).

(4) Install clevis pin and cotter pinto secure yoke

to slack adjuster.

leaks.

4-39.

a.

(5) Connect two brake hoses to brake chamber.

(6) Close drain valves on air resevoirs (fig. 4-79).

(7) Pressurize air brake system and check for

Brake Chamber—Fail-Safe Test and Re-

placement, M967, M969, and M970 except

M970 SN TC-0843, TC-0844, and TC-103 thru

TC-178.

Test.

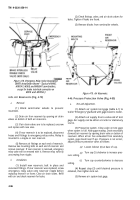

Perform leakage test (para 4-37). The

fail-safe unit will also be pressurized when the emergency

line is connected.

b.

Replacement of Fail-Safe Unit.

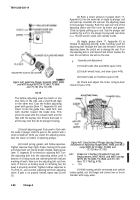

(1) Manually cage the spring in the fail-safe unit

(para 2-4).

(2) Release air pressure by opening drain valves on

both air reservoirs (fig. 4-79), then disconnect air lines and

tag for identification at installation.

(3) Tag brake hoses and disconnect them from brake

chambers and relay valve.

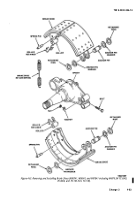

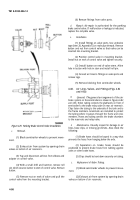

(4) Remove nut and capscrew from clamp ring

which secures fail-safe unit to brake chamber (fig. 4-72).

(5) Spread the clamp ring. Hold the diaphragm on

the non-pressure half and remove the fail-safe unit.

(6) Carefully install new fail-safe unit over diaphragm

on non-pressure housing.

CAUTION

DO NOT overtighten clamp

on air chamber, Maximum

torque should be 20-25 lb.-ft.

Over-thightening will distort

the flange and cause leakage.

(7) Install clamp ring, with capscrew, nuts, and

identification tag (fig. 4-72). Position the ports on the

4-90

Change 3

Back to Top