TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 232 of 528

TM 9-2330-356-14

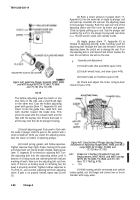

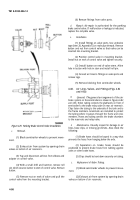

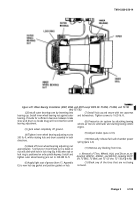

Figure 4-78. Emergency Relay Valve Installation

(M970 installation shown – Typical of M967,

M967A1, M969, and M969A1 semitrailers,

except for brake interlock connection on

M970 and M970A1).

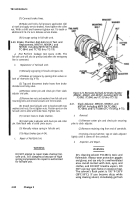

4-45. Air Reservoirs (Fig. 4-79)

a.

Removal.

(1) Block semitrailer wheels to prevent

movement.

(2) Drain air from reservoir by opening air drain

valves on bottom of both air reservoirs.

(3) If air drain valves are to be replaced, unscrew

and replace with new ones.

(4) If rear reservoir is to be replaced, disconnect

hoses and fittings to emergency relay valve. Relay is

mounted to a nipple on rear reservoir.

(5) Remove air fittings on each end of reservoir.

Remove two mounting bolts on each end of reservoir and

remove reservoir. If rear reservoir is removed, emergency

relay valve will be removed with it. Remove relay valve by

unscrewing from nipple.

b.

Installation.

(1) Install new reservoir, bolt in place and

reconnect fittings. If rear reservoir was replaced, screw

emergency relay valve onto reservoir nipple before

replacing reservoir on frame. Close air drain valves. Refill

with air and check reservoir for leaks.

(2) Check fittings, valve, and air drain valves for

leaks. Tighten if leaks are found.

(3) Remove blocks from semitrailer wheels.

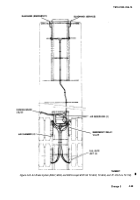

Figure 4-79. Air Reservoirs.

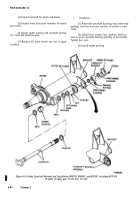

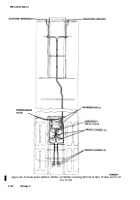

4-46. Pressure Protection Valve (Fig. 4-80)

a.

Test and Adjustment.

(1) Attach air system test gage (table 4-1) to

trailer “Emergency” gladhand with gage closest to trailer.

(2) Attach air supply line to valve end of test

gage. Air supply can be either a tractor or stationary

source.

(3) Pressurize system. Close valve on test gage

when system is full. Note gage reading. Drain secondary

(forward) air reservoir by opening drain valve on bottom of

reservoir. When all air has exhausted from secondary

system, gage should read 75 psi. If pressure is not correct,

adjust pressure protection valve as follows:

(a)

(b)

sure setting.

(c)

setting.

Loosen locknut (4) at base of cap.

Turn cap (5) clockwise to increase pres-

Turn cap counterclockwise to decrease

(4) Repeat step (3) until desired pressure is

obtained, then tighten lock nut.

(5) Remove air system test gage.

4-96

Back to Top