TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 228 of 528

TM 9-2330-356-14

(7) Connect brake lines.

(8) Make and hold a full pressure application (fall

air tank and apply service brakes). Hand tighten the collet

nut. With a drift and hammer tighten nut 1½-teeth or

additional 3/16 of a turn. Release service brakes.

(9) Uncage spring in fail-safe unit.

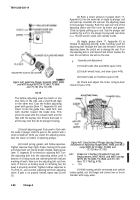

4-40. Brake Chamber-Fail-Safe Unit Test and

Replacement, M967A1, M969A1, and

M970A1 including M970 SN TC-0843,

TC-0844, and TC-103 thru TC-178.

a.

Test.

Perform leakage test (para 4-38). The

fail-safe unit will also be pressurized when the emergeney

line is connected.

b.

Replacement of Fail-Safe Unit.

(1) Manually cage spring in hit-safe unit (para 2-4).

(2)

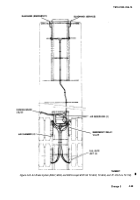

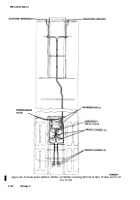

Release air pressure by opening drain valves on

both air reservoirs (fig. 4-79).

(3) Tag and disconnect brake hoses from brake

chambers and relay valve.

(4)

Remove cotter pin and clevis pin from slack

adjuster and yoke.

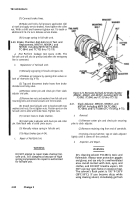

(5)

Remove two nuts and washers from fail-safe unit

mounting bolts and remove fail-safe unit from bracket.

(6) Install new fail-safe unit to bracket with two

washers and nuts. Do not tighten nuts. Position ports on the

fail-safe unit to aline with brake hoses. Tighten nuts.

(7) Connect hoses to brake chamber,

(8) Install yoke to adjuster with clevis pin and cotter

pin. Bend back ends of cotter pinto secure.

(9) Manually release spring in fail-safe unit.

(10) Adjust brakes (para 4-34).

c.

Repair of Fail-Safe Unit.

WARNING

DO NOT attempt to repair brake chamber fail-

safe unit. It is dangerous because of high

spring compression. No repair is authorized

for fail-safe unit.

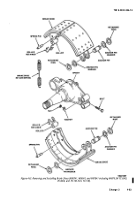

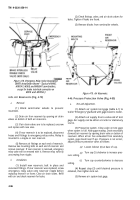

Figure 4-74. Removing Fail-Safe Air Brake Chamber

(M967A1, M969A1, and M970A1 including M970 SN

TC-0843, TC-0844, and TC-103 thru TC-178).

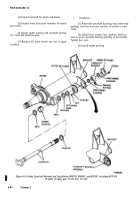

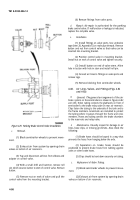

4-41.

Slack Adjuster, M967A1, M969A1, and

M970A1 mcluding M970 SN TC-0843,

TC-0844, andTC-103thruTC-178 (Fig. 4-75).

a.

Removal.

(1) Remove cotter pin and clevis pin securing

yoke to slack adjuster.

(2) Remove retaining ring from end of camshaft.

(3) Using a brass hammer, tap on slack adjuster

lightly until it comes off the camshaft.

b.

Inspection and Repair.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only In a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100 “F-138“F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

4-92

Change 3

Back to Top