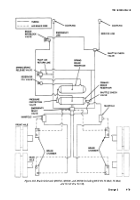

TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 225 of 528

TM 9-2330-356-14

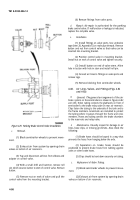

(2) Check for leakage indicated by bubbles. No

leakage is permissible.

CAUTION

DO NOT ovetighten clamp on air chamber.

Maximum torque should be 20-25 lb.-ft. Ov-

er-tightening will distort the flange and cause

more leakage.

(3) If leakage is found at flange, tighten the

clamp. If leakage is found at connections, tighten fittings.

(4) After initial brake application forces out a

small amount of air, no air should be expelled from the air

chamber. If air continues to exhaust, repair or

replacement of the air chamber is necessary.

b.

Removal.

(1) Disconnect brake hoses from brake chambers

or relay valve.

(2) Remove U-bolt and two nuts securing

chamber to bracket.

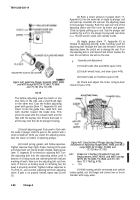

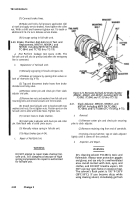

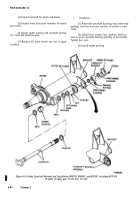

(3) Use adrift (fig. 4-70), or other blunt tool, and

hammer to loosen the collet nut.

NOTE

It may be necessary to remove the whole

brake assembly from the axle before un-

screwing the brake chamber, due to possible

bracket interference.

(4) Remove brake chamber by unscrewing it from

plunger housing.

(5) At this time the wedge assembly can be

removed for inspection or replacement (para 4-35).

c.

Repair.

Refer repair of brake chamber to direct

support maintenance.

d.

Installation.

(1) Check position of the wedge in plunger

housing to make certain wedge assembly is properly

seated (para 4-35).

(2) Thread collet nut (fig. 4-70) onto housing

tube. Apply a non-hardening sealer (item 25, Appendix E)

to the first three threads of the housing tube.

(3) With collet nut loose, turn the brake chamber

into the plunger housing until it bottoms.

(4) Aline connection ports with brake lines, if

necessary, by unscrewing brake chamber not more than

one full turn.

(5) Install U-bolt and two nuts to secure brake

chamber to bracket.

(6) Connect brake line.

(7) Make and hold a full pressure brake

application. Hand tighten the collet nut. With a drift and

hammer tighten collet nut 1½-teeth or additional 3/18 of a

turn. Release brake pressure.

(8) Check for leaks at flange and connections

(step

a).

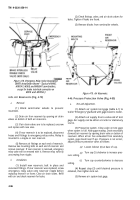

4-38.

Brake Air Chamber Test and Replacement,

M967A1, M969A1, and M970A1 including

M970 SN TC-0843, TC-0844, and TC-103 thru

TC-178 (Fig. 4-71).

a.

Test.

(1) With towing vehicle connected and vehicle

brakes applied, coat the flanges and connections on the air

chamber with soapy water.

Figure 4-70. Removing Brake Chamber (M967, M969, and

(2)

Check for leakage indicated by bubbles. No

M970 except M970 SN TC-0843, TC-0844, and TC-103 thru

leakage is permissible.

TC-178).

Change 3

4-89

Back to Top