TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 456 of 528

TM 9-2330-356-14

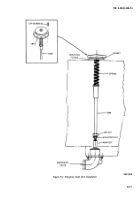

8-17. Manifold Drain Valve (Fig. 8-21)

c.

Cleaning and Inspection.

NOTE

It is not necessary to remove valve to replace

packing.

a.

Removal.

Remove valve (para 4-90).

b. Disassembly.

(1) Secure valve.

(2) Loosen packing nut (1) and turn hand wheel

(2) counterclockwise to force packing (3) and packing

gland (4) free of bonnet (5).

(3) Remove nut (6) and hand wheel (2).

(4) Remove packing nut (1), packing gland (4),

and packing (3).

TA502312

Figure 8-21. Manifold Drain Valve.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean all metal parts in dry cleaning solvent

(item 11, Appendix E) and dry thoroughly.

(2) Inspect for cracks in valve.

d. Assembly.

(1) Install packing (3), packing gland (4), and

packing nut (1). Tighten packing nut two full turns.

(2) Assemble hand wheel (2) and nut (6).

e.

Installation.

Install valve (para 4-90).

8-18. Filter/Separator Automatic Drain Valve

(M969, M969A1, M970, and M970A1)

(Fig. 8-22)

a.

Test.

A leak from the drain valve is an indication

that either the diaphragm valve or the separator control

valve is leaking. To determine which valve is leaking:

(1) Disconnect the tube fitting at rear of

diaphragm assembly (fig. 8-22).

(2) Dispense fuel through filter/separator and

visually watch for leakage.

(3) If leakage continues, the problem is in the

diaphragm valve and could be:

(a) Dirt under seat.

(b) Damaged O-rings.

(c) Stem hanging up.

If the stem is hung up, a

moderate blow with a rawhide mallet to the bottom cap of

the diaphragm valve might free the sticking stem.

(d) Vent plugged.

If vent is plugged, clean

hole in vent plug (fig. 8-22) with a .020- to .030-inch

diameter wire.

(4) If leaking stops, this is an indication that the

problem is in the separator control valve.

8-26

Back to Top