TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 450 of 528

TM 9-2330-356-14

Section VI. VALVES

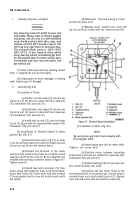

8-10. Gate Valve (Fig. 8-14)

NOTE

It is not necessary to remove valve to repair.

a.

Removal.

Remove valve (para 4-85).

b.

Disassembly.

(1) Secure valve.

(2) Remove eight capscrews (1), lockwashers (2),

and nuts (3). Lift upper hand wheel assembly from valve

body. Remove gasket (4), and clean mating edges of valve

body and hand wheel assembly.

(3) Loosen packing nut (5) and turn hand wheel

counterclockwise. This will force the spring (6), gland (7),

and packing (8) free of the bonnet (9).

(4) Secure stem (10), and remove nut (11) and

hand wheel (12).

c.

Cleaning

and Inspection.

WARNING

Dry cleaning solvent P-D-680 Is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean metal parts with dry cleaning solvent

(item 11, Appendix E) and dry thoroughly.

(2) Inspect for cracks and pitting.

(3) If disc assembly (13) or its mating surfaces in

valve body are pitted or scored, replace entire valve.

d,

Assembly.

(1) Place packing (8), gland (7), spring (6), and

packing nut (5) on stem (10). Tighten packing nut two full

turns only.

Figure 8-14. Gate Valve,

(2) Place gasket (4) in position, and install bonnet

assembly on body. Ensure that disc assembly (13) is at a

right angle to pipe opening. Install eight capscrews (1),

lockwashers (2), and nuts (3).

(3) Place hand wheel (12) and nut (11) on stem.

Turn hand wheel clockwise to seat valve.

e.

Installation.

Install gate valve (para 4-85).

8-20

Back to Top