TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 444 of 528

TM 9-2330-356-14

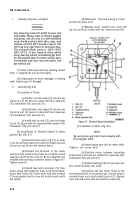

c.

Cleaning, Inspection, and Repair.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). if you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean all metal parts with dry cleaning

solvent (item 11, Appendix E) and dry thoroughly.

(2) Inspect gears for worn, damaged, or missing

teeth. Replace gears if damaged.

d.

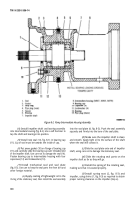

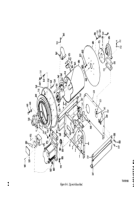

Assembly (Fig. 8-8).

(1)

Assembly of Frame.

(a)

Position one side angle (72) onto the two

frames (6 and 15). Secure in place with four capscrews

(71), lockwashers (68), and nuts (69).

(b)

Install other side angle (72) onto the two

frames (6 and 15). Secure in place with four capscrews

(71), lockwashers (68), and nuts (69).

(c)

Install both tie rods (70) onto the frames

(6 and 15). Secure with four capscrews (66), washers (67),

lockwashers (68), and nuts (69).

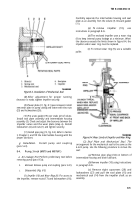

(2) Installation of Terminal Board in Motor

Junction Box.

(a)

Install the two nuts (2, fig. 8-7) on studs

(1) on the terminal board (3). Install the middle capscrew

(4) and one nut (5) onto the terminal board.

(b)

Position the terminal board in the motor

junction box (6). Install screw (7), but do not tighten.

Install capacitors (8 and 9) onto screw (7). Be sure

capacitors are installed with marking in position shown in

figure 8-7. Tighten screw (7).

(c)

Install lead with terminal (11, fig. 8-7)

from motor along with capacitor lead to terminal board.

Secure with screw (10). Install motor lead and capacitor

lead to screw (4). Install second nut (5) and tighten.

(d)

Reconnect hose reel wiring in motor

junction box (para 4-27).

(e)

Replace motor junction box cover (53,

fig. 8-8) and secure in place with four machine screws (52).

(3)

Installation of Motor (Fig. 8-8).

NOTE

Be sure pinion gear teeth mesh properly with

the ring gear teeth.

(a)

Install pinion gear (62) on motor shaft.

Tighten set screw (61).

(b)

Position motor between mounting

bracket (60, fig. 8-8) and frame (6). Install four capscrews

(57), lockwashers (58), and nuts (59).

(c)

Install bushing (56) into junction box

(55). Install assembly onto motor.

(d)

Connect the two motor leads to the

terminal board (63) in the junction box. Connect leads to

terminal board and install conduit (para 4-27). Replace

cover (53) and secure with four machine screws (52).

(4)

Drum Assembly.

(a)

Attach bevel gear (51, fig. 8-8) to disc

(47) with six screws (49) and shakeproof washers (50).

Attach ring gear (46) to disc (47). Use six spacers (48)

between the ring gear and disc, and secure with six screws

(44) and lockwashers (45).

(b)

Position the support collar (40) on disc

(47), and secure with six capscrews (41), lockwashers (43),

and nuts (42).

(c)

Install swing joint (30) through support

collar (40) and tighten set screw (39).

(d)

Install a new O-ring (38) between

adapter elbow (29) and outlet elbow (37). Secure the

outlet elbow to the adapter elbow with four capscrews (35)

and lockwashers (36).

(e)

Screw adapter elbow (29) onto swing

joint (30).

(f)

Install axle shaft (34) to adapter elbow

(29) with capscrew (31), lockwasher (32), and nut (33).

(g)

Install four spacers (28) onto disc (47)

using four studs, lockwashers (76), and nuts (75).

(h)

Install drum (26) over the four spacers

(28), lockwashers (76), and nuts (75).

8-14

Back to Top