TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 437 of 528

TM 9-2330-356-14

(3)

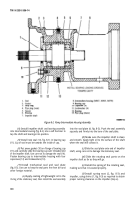

Intermediate Housing Assembly. The

arrangement of the bearings, spacer, seals, and impeller

shaft in the intermediate housing are the same as the

4-inch pump. To disassemble the intermediate housing,

use instructions in paragraph 8-3c.

d.

Cleaning. See

paragraph 5-8.

e.

Inspection and Repair.

Refer to figure 8-4 for wear

limits on impeller wear ring. Refer to paragraph 8-3e for

inspection and repair of remainder of parts.

f.

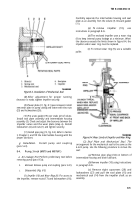

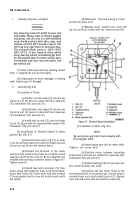

Assembly (Fig. 8-5).

(1) Assemble seals, bearings, spacer, and

impeller shaft in intermediate housing (para 8-3f).

(2) Install mechanical seal and seal plate using

instructions in paragraph 8-3f, step 7. Fasten seal plate (15,

fig. 5-5) to intermediate housing with eight capscrews (28)

and lockwashers (27).

(3) If wear ring (9) is being replaced, install new

wear ring in bore of volute (7). Make sure the ring is

squarely and firmly seated in the bore.

(4) Install impeller (10) on impeller shaft and

tighten securely.

(5) Install new gasket (11) over studs (8) on

volute (7). Carefully install the seal plate and

intermediate housing assembly over studs (8) on volute,

and fasten with twelve nuts (17) and lockwashers (16).

(6) Rotate the pump by hand to make sure the

impeller is not binding or scraping. Shims (12) can be

added behind the impeller to center the impeller in the

volute. The clearance between the front of the impeller

and the seal plate should be equal to the clearance

between the back of the impeller and the pump casing

(fig. 8-4).

g. Installation.

Install pump and pump coupling

(para 5-22).

Section Ill. HOSE REELS

8-5.

Hose Reels – 2½-inch (Fig. 8-6)

a.

Removal.

Remove hose reel (para 5-23).

b.

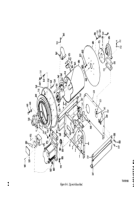

Disassembly (Fig. 8-6).

(1) Drum Disassembly.

(a)

Remove two capscrews (1), lockwashers

(2), and flat washers (3) securing the pinion bearing

assembly (hose reel lock) (5) to the front frame (6).

Remove the pinion bearing assembly (5), spacer (4), and

guard (75).

(b)

Attach a suitable hoist to drum (48), and

remove two capscrews (7), flat washers (8), lockwashers

(9), and nuts (10). Then remove two capscrews (11), flat

washers (12), lockwashers (13), and nuts (14). Lift drum

assembly from front and rear frame (6 and 15), and place

on a suitable workbench. Be sure to keep the two spacers

(16 and 17) with the drum assembly.

(c)

Remove six capscrews (18) and

lockwashers (19) securing the swivel joint (20) to the

adapter elbow (34). Remove the swivel joint (20) and

O-ring (21). Discard the O-ring.

(d)

Remove six nuts (76), lockwashers (77),

and studs (23) securing the disc (22) to the six spacers (24).

Remove the disc.

(e)

Remove the six screws (25) and

lockwashers (26). Remove the ring gear (27) and six

spacers (28).

(f)

Remove six capscrews (29) securing the

bevel gear (30) to the disc (22). Remove the bevel gear.

(g)

Remove capscrew (31), lockwasher (32),

and nut (33) securing the adapter elbow (34) to the axle

shaft (35). Remove the adapter elbow (34). Remove four

capscrews (36) and lockwashers (37), and remove the

outlet elbow (38) and O-ring (39). Discard the O-ring.

Remove four capscrews (40) and lockwashers (41), and

remove outlet adapter (42) and O-ring (43), Discard the

O-ring.

(h)

Remove drum (48).

(i)

Loosen set screw (44), and pull axle shaft

(35) and bearing and collar (45) from the disc (46) and

collar (47). Put axle shaft in a bench vise and loosen set

screw on bearing collar. Use a punch to rotate collar

clockwise to release bearing and collar from axle shaft.

NOTE

Take note of how many thrust washers, If any,

are used between spacers and disc.

(j)

Remove six nuts (78), lockwashers (77),

studs (49), and thrust washers (50). Remove six spacers

(24).

8-7

Back to Top