TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 433 of 528

TM 9-2330-356-14

WARNING

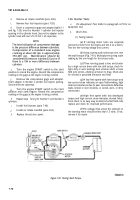

(b) Then remove enough shims to move the

impeller away from the wear plate a distance of 0.015-inch.

Be careful when removing the Impeller from

(c)

Rotate the pump by hand to make sure

the pump. The spring load on the mechanical

the impeller is not binding or scraping.

seal may cause the impeller to fly off the shaft

as it is being removed, causing serious injury

(d)

Minor nicks on edges of impeller vanes

to personnnel.

can be removed by finishing with a fine stone.

(c)

Apply force to strap wrench in a

(e)

If the impeller and wear plates are worn

count counterclockwise direction. Using a block of hard wood

excessively, they must be replaced.

and a hammer, hit the hub of impeller to loosen it on the

(f)

After replacement of the impeller, wear

shaft. Remove the impeller by unscrewing it from the

plate, or impeller shaft, check for clearance between the

impeller shaft.

BACK of the impeller and the seal plate. If the impeller

(4) Pull the seal plate (15) and the mechanical

scrapes when the seal plate (15) is installed, add another

seal (16) from the impeller shaft.

gasket (19) of sufficient thickness between the seal plate

and the pump casing.

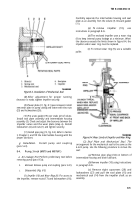

(5) Remove four capscrews (12) and lockwashers

(13) from bearing cap (11). Remove the bearing cap and

discard gasket (10).

(6) Remove pump coupling (28) and key (29)

from opposite end of shaft, if these items were not already

removed.

(7) Using a soft hammer, hit the keyed end of the

impeller shaft to remove the shaft (8), bearings (9 and 6),

and spacer (7) from intermediate housing (3).

(8) Remove seal (5) from intermediate housing.

Discard the seal.

(9) Remove the seal (14) from the bearing cap

(11). Discard the seal.

(2)

Mechanical Seal (16).

Inspect the mating

surfaces of the seal for wear, scoring, grooves or other

damage which can cause leakage. If any of the seal parts

are worn, replace the entire seal. Never mix old and new

parts of a seal.

(3) Impeller Shaft (8).

Inspect the impeller shaft

for nicks, scratches, scoring or other damage. Replace the

shaft if damaged.

(4)

Bearings (6 and 9).

Rotate bearings by hand

and check for binding or wear. Replace bearings if wear is

found. The bearings are a light press fit on the impeller

shaft and a snug push fit in the housing. If the shaft is worn

so the bearing slips on and off easily, the shaft must be

replaced. Replace the housing if the bearings do not fit

snugly into the bearing bore.

(10) Remove snap ring (27), bearing (9), and

(5)

Gaskets and Seals.

Whenever a pump is

bearing (6) from impeller shaft (8).

overhauled, ail gaskets should be replaced. However, if

old gaskets must be reused, soak the gaskets in water to

(11) The wear plate (21) is fastened to the volute

prevent them from drying out and shrinking. Inspect all

with two nuts (25) and lockwashers (26). Remove the wear

seals carefully and replace any that are damaged.

plate only if excessive wear is evident and replacement is

necessary (step e).

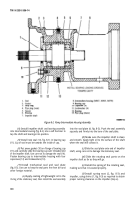

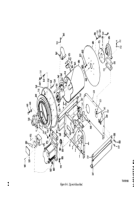

Assembly (Fig 8-1).

d.

C[eaning.

Refer to paragraph 5-8.

(1) Install new seal (5) in bore of intermediate

housing. Lip of seal must be toward the impeller.

e.

Inspection and Repair (Fig. 8-1).

NOTE

(1) Impeller and Wear Plate. The

open impeller

(20) uses a wear plate (21) in front of the impeller vanes to

minimize internal pump leakage. This wear plate normally

receives most of the wear. Pump efficiency will decrease

considerably when the clearance between the wear plate

and impeller exceeds 0.035-inch. Normally, shims (18) can

be added to bring clearance within limits.

(a)

Add shims until rubbing just starts to

occur when the impeller and wear plate are secured in

place.

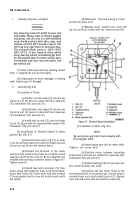

Loading groove in bearings must be installed

toward the shoulder or center (largest

diameter) of the impeller shaft.

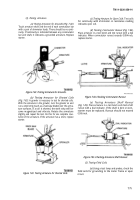

(2) Press bearing (9) over threaded end of

impeller shaft (8) and install snap ring (27).

(3) Put spacer (7) onto impeller shaft against

bearing just installed. Press bearing (6) with loading

groove towards spacer onto keyed end of impeller shaft

(fig. 8-2).

8-3

Back to Top