TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 428 of 528

TM 9-2330-356-14

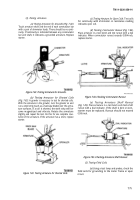

(b)

Inspect all connections to be sure that

they are properly clinched and soldered. Inspect the

insulation for evidences of damage.

(c)

The only way to check for field coil

shorts is to use the starting motor bench test.

(4)

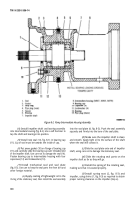

Testing Brush Springs (Fig. 7-86).

Measure

brush spring tension with a tension meter. Push the brush

and take a reading just as the brush projects a little from

the brush holder. On a new brush the spring tension

should be 32-40 ounces. If brush spring tension is below 20

ounces, replace. Spring tension can be changed by twisting

the spring at the holder with long nose pliers.

Figure 7-86. Testing Brush Spring Tension.

(5)

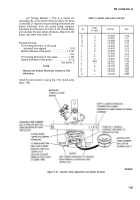

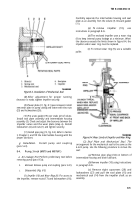

Testing Solenoid Switch (Fig. 7-87).

(a)

Ensure that plunger moves freely in coil.

Measure the pull-in coil current draw by using Test A.

Current should not exceed 16 amps.

(b)

Measure the hold-in draw using Test B.

Current should not exceed 6 amps.

(c)

Total hold and pull current draw using

Test C is 22 amps. Total current draw should not exceed 25

amps.

(d)

Replace a solenoid that does not meet

these test specifications.

c.

Test After Reassembly.

(1) After the motor is assembled, check the

armature end play by inserting thickness gage between

thrust washer (21, fig. 7-62) and pinion housing (22). End

play should be between 0.005-inch and 0.030-inch. Adjust

end play by adding or removing thrust washers (21,

fig. 7-62) on the commutator end of the armature.

(2) Before installing, check the pinion clearance.

Proper clearance is important to ensure starter engage-

ment. Press on solenoid core to shift the pinion into full

mesh. Measure the clearance between pinion and pinion

stop (fig. 7-87). Clearance should be 0.07 to 0.12-inch. Ad-

just the link screw on the end of the solenoid plunger for

proper clearance.

Figure 7-87. Testing Solenoid Switch.

Figure 7-88. Checking Pinion Clearance.

7-72

Back to Top