TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 429 of 528

TM 9-2330-356-14

7-91.

Alternator Test and Adjustments

a.

Test, On Equipment.

Before doing the following

test, check battery condition (para 3-6 and 4-23),

alternator drive belt (para 4-78), and wiring and

connections (para 4-16).

(1) Connect an accurate voltmeter across the

batteries and check battery voltage with engine not

running. Record the voltage.

(2) Now start the engine and run it at

approximately 1000 rpm. The voltmeter should show an

increase from the reading obtained in step (l). If the

voltage rises excessively (over 14.2V), the charging system

may be defective or the voltage regulator needs

adjustment.

NOTE

Do not attempt to adjust regulator voltage if

batteries are in low state of charge. System

voltage will Increase as the batteries receive

a charge.

b.

Voltage Adjustment. If

batteries are constantly

undercharging or overcharging, and all other causes, such

as bad connections, damaged wiring, or slipping drive belt

have been checked, make the following adjustment:

(1) Connect an accurate voltmeter across

batteries and run engine at approximately 1000 rpm.

CAUTION

the

Do not attempt to turn the adjustment screw

past its internal stops or damage will result.

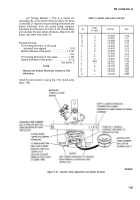

(2) Remove nylon screw (fig. 7-89) from voltage

regulator. Turn adjustment screw with a small screwdriver

and attempt to bring voltage to proper setting

(13.6-14.2V). The ideal setting will be a value which

maintains the batteries in a fully charged condition

without excessive water usage.

(3) Install nylon screw after adjusting to prevent

entrance of dirt and water.

(4) If output voltage is excessively high and

cannot be lowered by turning the adjustment screw,

replace voltage regulator.

(5) If output voltage is low and cannot be

increased by turning the adjustment screw, remove the

alternator for further testing and repair.

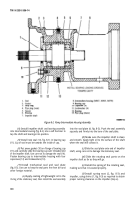

Figure 7-89. Voltage Adjustment.

c.

Bench Test.

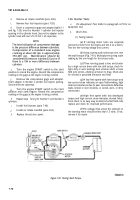

This test can be performed to

determine if the fault is in the alternator, voltage

regulator, or diode trio. Because the voltage regulator is

built into the alternator, the test block arrangement is

simple. If a commercial test block is not available. use the

arrangement shown in figure 7-90.

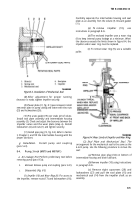

Figure

7-90.

Test Block Arrangement.

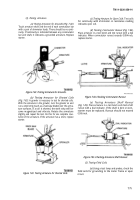

(1) Connect one end of a short jumper lead to

negative output terminal. Connect opposite end of

jumper lead to a short stiff piece of wire at least 11/2-inches

long. Insert this wire into the small hole in end of brush

holder so that it firmly contacts the outer brush terminal

(fig. 7-91). This procedure overrides the voltage regulator

and gives a full field condition.

7-73

Back to Top