TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 422 of 528

TM 9-2330-356-14

(3) Timing

Method 2.

Flow Timing the Pump.

CAUTION

When removing tappets which contain timing

buttons, do not allow the portion of the injec-

tion pump which has the face gear to be lifted

from its position.

(a)

Install a Number 11 or standard timing

button in injection pump. Install pump on engine

(para 7-48).

(b)

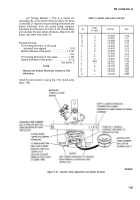

Remove delivery valve cap nut and

delivery valve holder (fig. 7-77). A 12-point socket or box

wrench must be used on delivery valve holder to keep

from damaging this part. Lift out delivery valve spring

only, and leave it out, replacing delivery valve holder and

delivery valve cap nut and gasket.

(c)

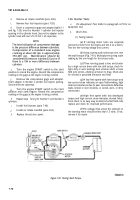

Turn flywheel (fig. 7-78) clockwise until

Number 1 cylinder (closest to blower wheel) is on com-

pression stroke, which follows closing of intake valve.

(d)

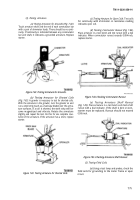

Set control unit lever on injection pump

to wide open or up position (compress stop solenoid

plunger spring or remove stop solenoid assembly).

Connect Number 1 cylinder fuel line to Number 1 pump

outlet so that fuel line projects from the engine, hanging

down (fig. 7-15). Position receptacle for fuel under the

line. Connect lines from fuel supply to transfer pumps,

transfer pumps to filter, and filter to injection pump.

Operate fuel transfer pumps to obtain fuel pressure at

injection pump. This can be done on the unit by turning

engine switch to RUN. Rotate flywheel about l-inch

counterclockwise so that P.C. mark (fig. 7-78) is below

timing pointer hole.

(e)

Rotate blower flywheel clockwise until

fuel flows from Number 1 cylinder fuel line. Continue

rotating slowly clockwise until fuel stops flowing. The

point at which fuel stops flowing from Number 1 cylinder

fuel delivery line is the injection pump port closing point.

Stop rotation of engine at exactly the port closing point (1

to 2 drops in 5-10 seconds).

(f)

Check timing pointer in the timing port

on the side of the generator adapter (fig. 7-78). If timing

pointer coincides with the P.C. mark stamped on flywheel,

the injection pump button thickness is correct. If the P.C.

mark on the flywheel is below the pointer, injection pump

is closing early, and will require a thinner button. If the

P.C. mark on flywheel is above the pointer, injection pump

is closing late and will require a t bicker button. Each mark

on flywheel indicates a difference of 0.006-inch button

thickness or two steps in button code number. (Example:

The P.C. mark on flywheel is above pointer. The pointer

indicates 1½ marks difference. A button 0.009-inch

thicker or three steps difference in button number code is

indicated. Since Number 11 button is installed, a letter C

button is needed.)

(g) Remove injection pump and insert

proper timing button, taking the same precautions not to

lift the assembly containing face gear when removing

timing button.

(h)

Repeat injection pump installation.

Figure 7-77. Delivery Valve.

7-66

Back to Top