TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 417 of 528

TM 9-2330-356-14

Figure

7-68.

Heat Sink Mounting.

(3)

Install insulating bushings (26) into heat sinks

(21 and 22). Position heat sinks in the slip ring end housing

(31) and fasten with two capscrews (15), lockwashers (16),

guard washers (17), and insulating washers (18). Do not

tighten (fig. 7-68).

(4) Install capacitor (25), clamp (24), and three

screws (23).

(5) Replace the gasket (36) and regulator housing

(37).

NOTE

Be sure mating surfaces of heat sinks,

terminals, and terminal screws are clean and

free of paint to ensure a good electrical

connection.

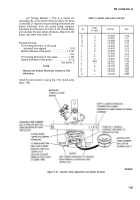

(6) Install the regulator lead wires to the

terminal bolts. Red wire goes on the positive terminal

screw (19), and black wire goes on negative terminal screw

(20).

(7) Install terminal bolts through heat sinks, slip

ring end housing (31), and regulator housing (37). Ensure

that red and black regulator leads (fig. 7-69) are properly

routed through cutaway section of end housing (31).

(8) Install two nuts (38) on terminal screws (19

and 20). Tight en nuts. Loosely install two washers (39) and

nuts (40).

(9) Tighten lower heat sink screws (15) and check

all leads for proper routing. Ensure that no lead is pinched

under heat sink.

(10) Reinstall stator and terminal nuts. It is

advisable to aline stator (14) and housing (31) by

temporarily installing the through bolts (5).

(11) Press drive end bearing (8) into housing (7),

and reinstall bearing retainer (9) and four screws (10).

Figure

7-69.

Installing Regulator Leads.

(12) Press drive end housing (7) and bearing (8)

onto rotor shaft.

(13) Install rotor (12) and housing (7) assembly

into stator (14) and slip ring end housing (31) assembly,

being sure to aline mounting ears.

(14) Install three through bolts (5), washers (6),

and self-locking nuts (32). Tighten nuts to 50-60 lb.-in.

Place a small amount of SRI 2 grease in housing and

reinstall the metal dust cap (33) by carefully pressing it

into place.

(15) Install diode trio and three nuts (fig. 7-65).

(16) Insert outer brush and spring assembly (44)

into the housing (37), and compress the brush spring. Use

a small screwdriver or similar tool. While holding the

spring compressed, insert a pin through the hole in the

rear of the housing so the spring will be held in a

compressed position. (A suitable pin can be made from a

piece of 1/16-inch drill rod.) Install and compress the

remaining brush and spring assembly (44) in a similar

manner. Hold the spring in a compressed position by

pushing the pin farther into the housing (fig. 7-70).

7-61

Back to Top