TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 410 of 528

TM 9-2330-356-14

c.

Inspection and Repair.

(1) Measure diameter of bypass valve

(3). If

measurement shows less than 0.3365-inch minimum

diameter, replace valve. Maximum diameter should not

exceed 0.3380-inch.

(2) Measure free length of valve spring (3). If

free length is less than 2.3125-inch (+/- 0.0625-inch),

replace valve spring.

(3) Inspect valve spring tension under load

conditions. Using a compression scale, compress valve

spring to 1.1875-inch, and check the scale for 2.225 lb.

(+ /-0.110 lb.) compression.

(4)

Inspect plug (1) for evidence of worn or

damaged threads. Replace plug if defective.

d.

Assembly.

(1) Assemble bypass spring (2, fig. 7-60) and

valve plunger (3), and install in bearing plate (4).

(2) Install recessed plug (1). Tighten plug

securely.

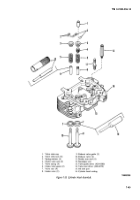

7-75. Gear Cover Assembly

a.

Disassembly (Fig.

7-28).

(1) Remove external retaining ring (1, fig. 7-28)

securing governor yoke (2) to the governor shaft (5), and

remove the yoke (2).

(2) Slide governor shaft free of the gearcase.

NOTE

Do not remove pressed-in components such

as bearings, seals, and plugs unless there is

evidence of damage, excessive wear or

looseness.

(3) Set the gearcase on wood supports.

(4) Using the combination main and cam bearing

driver tool (table 5-1 and fig. 7-36) and the oil seal driver

tool (table 5-1 and 13, fig. 7-28), drive out the oil seal (11).

(5) Using the valve guide driver tool (table 5-1),

drive out the needle bearing (7) and oil seal (6).

(6) Remove thrust bearing (8) and ball (9) if

defective.

b.

Cleaning.

WARNING

Dry cleaning solvent P-D-680 Is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, Immediately get fresh

air and medical help. If solvent contacts eyes,

Immediately wash your eyes with water and

get medical aid.

(1) Clean gearcase gasket mating surface using

dry cleaning solvent (item 11, Appendix E). Ensure that

mating surface is cleaned free of all excess gasket

material. Wipe dry using a clean, lint-free cloth (item 24,

Appendix E).

(2) Flush gearcase

clean with diesel fuel

(item 14, Appendix E) and clean out the oil passages using

a fine cleaning wire.

WARNING

Particles blown by compressed air can be

dangerous. Ensure that air stream is directed

away from the user and other personnel in the

area.

(3) Dry oil passages using clean, filtered com-

pressed air under moderate pressure of approximately

15 psi.

c.

Inspection and Repair.

(1) Visually inspect gearcase for nicks or dents on

the gasket mating surface. Inspect for cracks. Inspect bolt

holes for damaged or excessively worn threads. Replace

gearcase if damaged.

(2) Inspect all components for evidence of

excessive wear, scratches, and nicks. Replace defective

components.

(3) Measure distance from end of roll pin to

mounting face of gearcase. The distance should be

0.781-inch. If necessary to replace pin, the pin should be

positioned with open end facing crankshaft seal.

d.

Assembly (Fig.

7-28).

(1) Install thrust bearing (8, fig. 7-28) and ball

(9), and press bearing into position.

7-54

Back to Top