TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 407 of 528

TM 9-2330-356-14

NOTE

If the counterbore is damaged, it must be

machined for an oversized valve seat. Valve

seats are available in 0.005- and 0.010-inch

oversize diameters.

(d)

Cut valve seat to a narrow, 1/64-inch rind

(fig. 7-57) and remove rind using a

damage valve seat counterbore.

sharp tool. Do not

Figure 7-57, Removing Exhaustt Valve Seat.

(e)

Clean out valve scat counterbore, re-

move burrs from edges, and check counterbore diameter

(fig. 7-56).

the

NOTE

To facilitate valve seat installation, heat the

cylinder head in an oven at 325°F for

approximately thirty minutes and cool the

replacement valve seat in dry ice.

(f)

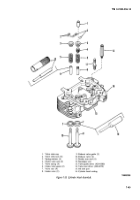

Install new replacement valve seat. Use

valve seat driver tool (table 5-1 and 14, fig. 7-55) to

ensure that valve seat sets evenly in the counterbore.

(g)

After installation, face each new valve

seat to a 45° angle for exhaust valve and a 42° angle for

intake valve, and a width of approximately 3/64- to 1/16-inch

(fig. 7-56). The finished seat face should contact

approximate center of valve face. Use Prussion Blue dye

(item 12, Appendix E) on the valve face to check contact

points with refaced valve seats. Make any corrections to

the valve seat, not the valve face.

(h)

Check

for 0.0300-inch minimum

clearance between valve head and cylinder head surface

(fig. 7-56). If necessary, regrind valve seat.

(4)

Valve Spring.

(a)

Inspect valve spring (5, fig. 7-55) for

evidence of damage. Replace spring if cracked, pitted, or if

ends are out-of-square.

(b)

Check valve spring for 1.875-inch free

length.

(c)

Inspect valve spring under load

conditions using a compression scale as follows:

1. Compress spring to 1.528-inch

(valve closed), and check scale for 45-49 lb. compression.

2. Compress spring to 1.182-inch

(valve open), and check scale for 87-97 lb. compression.

(d)

Discard springs that fail to meet above

requirements.

d.

Assembly (Fig. 7-55).

NOTE

The valve stem seal assemblies (4) are

installed on the Intake valve guides only.

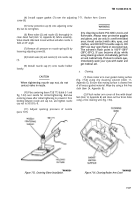

(1) Position a new replacement valve stem seal

assembly (4, fig. 7-55) on the intake valve guides only.

Apply a film of oil to inside surface of the valve stem seal.

(2) Apply a film of oil to the valve stem and insert

valve stem up into the valve guide. Check valve for tight

seal by making pencil marks at intervals on the valve face

and observe if pencil marks rub off uniformly when valve is

rotated 1/4 turn. If not a tight seal, regrind the valves.

(3) Using a valve spring compressor, compress

the valve spring (5) and spring retainer (3) sufficiently to

permit installation of the valve stem locks (2). Be certain

the valve spring locks are properly seated before releasing

the spring compressor.

(4) Repeat steps (1) through (3) to install

remaining intake and exhaust valve components.

7-73.

Piston and Connecting Rod

a.

Disassembly (Fig. 7-26).

(1) Usings ring expander, remove piston rings (1,

2, and 4, fig. 7-26) and oil ring expander (3) from each

piston.

(2) Remove two retaining

piston pin (6) from each piston.

rings (5) and push

7-51

Back to Top