TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 397 of 528

TM 9-2330-356-14

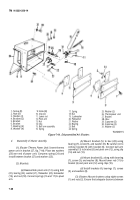

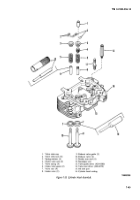

7-69. Fuel Injection Pump (Fig. 7-46)

(6) Remove the delivery valve holder(9), then lift

out the delivery valve spring (10), delivery valve (11),

a.

Disassembly (Fig. 7-46). All

work on injection

delivery valve body (42), and delivery valve spacer (12).

equipment MUST be performed in the cleanest location

possible. No filing, scraping, or sawing should be done on

(7) Remove the hydraulic head locating screw

the bench where repairs are made.

(13) and copper gasket (14).

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only In a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 10O”F-138°F

(38°C-590°C). if you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. if solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean all external dirt and grease from the

pump.

CAUTION

The pump housing must NEVER be clamped

in a vise.

NOTE

(8) Remove four head retaining screws (15) and

four head retaining clamps (16). Carefully rest tappet on

clean surface and using shaft head, hammer pump body

assembly until hydraulic head assembly separates from

body assembly.

(9) Remove the O-rings (18 and 19) from the

hydraulic head and the pump housing.

(10) Remove the tappet (20) and related O-ring

(21) from the face gear bore.

(11) Remove the spring ring (22) and the plunger

button (23) from the end of the plunger (the plunger is

part of hydraulic head assembly).

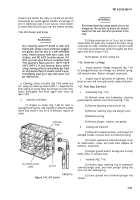

(12) Invert the hydraulic head assembly and place

it in a suitable arbor press (fig. 7-47).

(13) Position tool TSE 76215 (table 5-1) over the

lower spring seat washer (24, fig. 7-46) and depress the

plunger spring, then remove the lower seat (25).

(14) Remove lower spring seat washer (24,

fig. 4-46) and plunger spring (26).

(15) Place the hydraulic head assembly on a

bench. Use two screwdrivers to pry off the face gear (28),

then remove the thrust washer (29).

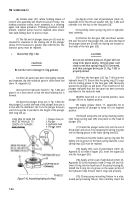

A special mounting fixture (table 5-2) must be

made to adequately secure the pump

NOTE

housing.

The plunger, plunger sleeve and hydraulic

head are mated parts and must always be

(2) Clamp the mounting fixture in a suitable vise.

kept together.

-

(16) Do not remove the plunger (35) from the

(3) Install the pump housing into the mounting hydraulic head

fixture with two two - 18 UNC hex head screws.

(4) Release lock tabs (2) and remove the two

control unit retaining plate screws (1), tab washers (2,

fig. 7-46), and the control unit retaining plate and stop

assembly (3). Carefully pull the control unit assembly (4)

with plunger sleeve pin (5) out of the pump housing (6).

Plunger sleeve pin Occasionally may have to be removed

separately. Use needle nose pliers or magnetic pencil.

(5) Remove the delivery valve cap nut (7) and

gasket (8).

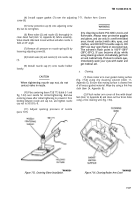

b.

Inspection (Fig. 7-46).

(1) Place the delivery valve assembly in test

fixture TSE 76226 (table 5-l), and secure in a suitable vise

(fig, 7-48).

(a)

Insert the delivery valve spring (1) and

the delivery valve holder (2). Tighten the delivery valve

holder to 70-75 Ib.-ft. Figure 7-77 illustrates the

components that are to be assembled to test fixture TSE

76226 (3).

7-41

Back to Top