TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 390 of 528

TM 9-2330-356-14

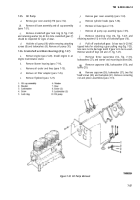

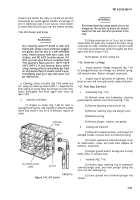

7-49. Oil Filter Adapter (Fig. 7-20)

a.

Clean all gasket material from oil filter adapter

(19, fig. 7-20) and cylinderblock. Attach oil filter adapter

(19) and new gasket (20) to cylinder block with three

capscrews (17) and lockwashers (18). Tighten capscrews to

45-50 lb.-ft.

b.

Attach all oil lines to oil filter adapter

(para 7-50).

c.

Install oil filter (para

4-72).

d.

Install elbow (15). Tighten

position 90° right of top center.

elbow securely to

e.

Attach oil cooler hoses 10 oil filter adapter

(para 7-59).

f

Replace blower housing (para 7-60).

7-50. Oil Lines (Fig. 7-20)

c .

a.

b.

tee (3).

tee(3).

d.

adapter

7-51.

a.

sides of

b.

c.

Connect oil line (6, fig. 7-20) to elbow (7).

Connect oil line (4) to adapter (5) and restricted

Connect oil line (2) to adapter (1) and restricted

Connect oil line (9) to elbow (10) on oil filter

(19) and restricted tee (14).

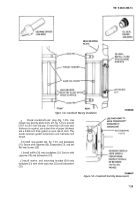

Oil Filler Tube (Figs. 7-18 and 7-19)

Apply adhesive (item 2, Appendix E) to both

new gasket (4, fig 7-19).

Position gasket (4) on filler tube (3).

Position both gasket and filler tube on engine

crankcase. Install two capscrews (1) and lockwashers (2),

and tighten.

d.

Position fuel filter adapter (1, fig. 7-18) and fuel

filters (2) onto engine crankcase. Install three capscrews

(3) and lockwashers (4), and tighten.

7-52. Exhaust Manifold (Fig. 7-17)

a.

Install exhaust manifold (4) and four new gaskets

(5) to cylinder heads. Secure with four lock tabs (1), eight

capscrews (2), and eight washers (3). Tighten capscrews

evenly to 13–15 lb.-ft. Bend lock tabs (1) up to prevent

capscrews (2) from loosening.

b.

Replace high temperature switch (para 7-57).

Replace exhaust pipe (para 4-77).

c.

Replace air shutter assembly (para 7-60),

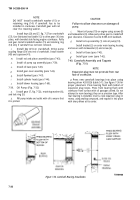

7-53. Engine Junction Box and Electrical Wiring

Refer to paragraph 4-19 for installation.

7-54. Fuel Stop Solenoid (Fig. 7-16)

a.

Connect lead from control switch terminal on

solenoid.

b.

Position solenoid on bottom cylinder pan and

install two screws. Be sure ground lead is installed by one

of the screws.

c.

Adjust solenoid plunger (para 7-85).

7-55. Fuel Lines (Fig. 7-15)

a.

Install injector lines (7).

b.

Install manifold (4) and return lines (5).

c.

Install injector nozzle return lines (3).

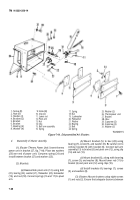

7-56.

Governor Linkage (Fig. 7-1 4)

a.

Using screws (13), lockwashers (14), and nuts (15),

attach governor control bracket (12) to engine backplate.

b.

Insert end of throttle rod (7) through two washers

(20) and into hole in control arm (19). Secure with cotter

pin (5).

c.

Attach throttle cable (11) to throttle arm (10)with

clevis pin (9) and cotter pin (8).

NOTE

If new ball joints are used on linkage, position

the new joints to obtain the same length or

1/32 inch more than the old linkage (one turn

equals 1/32 inch). If old linkage

length

is

not

available, position new ball

joints about

midway on each end of linkage, then lengthen

1/8-inch.

d.

Attach governor arm (3) to governor shaft (4) and

install spring (17). Attach opposite end of governor arm to

governor linkage (1). Connect governor linkage (1) to

injector pump (2).

7-57.

High Temperature Switch (Fig. 7-1 3)

a.

Assemble items 5-13 in order shown in figure

7-13.

b.

Install assembled pressure switch by securing

switch bracket (10) with two capscrews (3) and washers(4).

c.

Connect two leads (1 and 2) to high temperature

switch.

d.

Remove block from louvers on air shutter.

7-34

Back to Top