TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 395 of 528

TM 9-2330-356-14

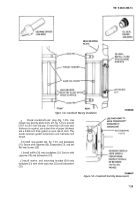

shutters and shutter box sides is maintained and that

brackets (4) are seated against shoulder of bearings (7)

prior to tightening screws (1) and nuts (2). Check shutters

to ensure that they fully open and close without bending.

7-65. Oil Cooler and Lines

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable, Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100”F-138°F

(38°C-590°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medlical aid.

a.

Cleaning.

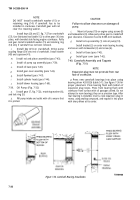

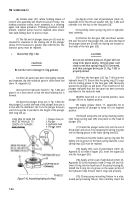

Clean oil cooler (fig, 7-45) inside and

out

using dry cleaning solvent (item 11, Appendix E).

Flush piping by forcing diesel fuel through oil cooler inlet.

Drain thoroughly and flush again with clean oil

(para 7-62).

b.

Inspection and Repair.

(1) Inspect on cooler (fig. 7-45) for bent or

damaged cooling fins, and cracked or defective welds

which may result in loss of oil. If defective, replace oil

cooler.

TA100116

Figure 7-45. Oil Cooler.

WARNING

Particles blown by compressed air can be

dangerous. Be certain to direct air stream

away from the user and other personnel in the

area.

(2) Using compressed air at 15 psi, test oil cooler

under water for leaks. Dry outside of oil cooler using

compressed air under moderate pressure, and flush inside

of oil cooler using diesel fuel. Drain thoroughly and flush

again with clean oil (para 7-62).

(3) Straighten all bent cooling fins.

7-66. Governor Linkage

a.

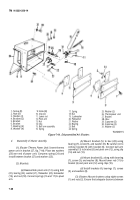

Inspect governor linkage components (fig. 7-14)

for damaged threads, bent linkage rod, defective spring,

and excessive wear. Replace damaged components.

b.

Inspect snap-in ball joints for tightness. If ball

joints are worn and come apart easily, replace ball joints.

7-67. Fuel Stop Solenoid

a.

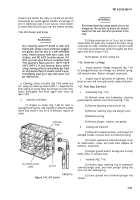

Disassembly (Fig. 7-16).

(1) Remove screw and lockwasher securing

ground lead to solenoid, and remove lead (fig. 7-16).

(2) Remove adjusting screw and jam nut.

(3) Remove retaining rings and plunger cover.

(4) Remove spring.

(5) Remove plunger, retainer, and gasket.

b.

Cleaning and Inspection.

(1) Wipe all components clean, and inspect for

damaged threads, excessive wear, and defective spring.

(2) Inspect waterproof solenoid plunger cover

for deterioration, cracks, and small holes. Replace all

defective components.

(3) Inspect ground lead for damage due to sharp

bends, kinks, or excessive wear.

c.

Assembly (Fig. 7-16).

(1) Position upper retaining ring in waterproof

solenoid plunger cover, and insert plunger spring into

cover over the retaining ring.

(2) Insert grooved end of solenoid plunger into

retainer.

7-39

Back to Top