TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 392 of 528

TM 9-2330-356-14

d.

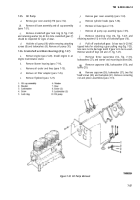

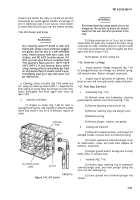

Blower Housing (6, Fig. 7-9).

NOTE

Be sure to attach the starter shroud to blower

housing.

(1) Position blower housing (6, fig. 7-9) on

engine. Attach to engine using eight capscrews (23), two

capscrews (24), two washers (25), capscrews (26), capscrew

(21), and lockwasher (22).

(2) Tighten capscrew (20).

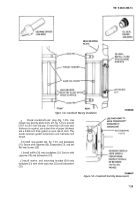

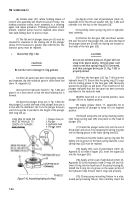

(3) Attach engine fan shroud (8, fig. 7-10) to

frame (9) and panel (5) with four capscrews (6) and nuts

(7).

(4) Attach fuel hoses to fuel tank (para 4-73) and

air cleaner hose to air intake manifold (para 4-74).

e.

Top Air Housing (2, Fig. 7-9).

(1) Position top air housing cover (2, fig. 7-9),

and secure to engine with four capscrews (18) and washers

(19).

(2) Position lifting bracket (17) and lifting bracket-

brace (9) on engine head covers. Secure to engine using

spacer (8), capscrew (7), two spacers (16), two vibration

cushions (15), two washers (14), and two capscrews (13).

(3) Replace muffler stand (3, fig. 7-10). Attach

with five capscrews (1) and nuts (2).

(4) Install muffler (para 4-77). Attach air cleaner

hose to air intake manifold para 4-74).

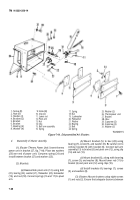

Section III. REPAIR INSTRUCTIONS

7-61.

General

a.

This section contains the procedures and

specifications for overhaul, reassembly, and checkout of

the auxiliary diesel engine components. The procedures

require use of precision instruments and machinery, and

should only be undertaken by qualified technicians.

Special

tools are referenced by National Stock Number

and Part Number in table 2-1, and should be used where

specified. The overhaul procedures are based on the

premise that the engine will be restored to a completely

serviceable condition as prescribed by maintenance

serviceability standards.

b.

The

diesel engine is a precision-built engine and,

therefore,

the repair and overhaul standards for

component parts have been fixed at extremely close

tolerances. The following should apply to all inspection

procedures:

(1) The latest inspection equipment, methods,

and procedures should be used during component repair

and overhaul.

(2) Extreme care must be exercised during all

phases of inspection. Repair and overhaul standards must

be followed exactly.

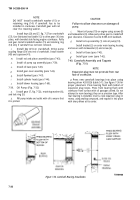

7-62. Cleaning - General

a.

Disassemble engine to major components in

accordance with instructions in Section II of Chapter 7.

b.

Clean all parts thoroughly and identify location in

engine.

c.

Maintain cleanliness throughout the overhaul

procedures. Diesel engines are intolerant to even minute

particles of dirt. Tools and equipment should also be clean.

d.

Cover all cleaned components to protect them

from dust or dirt.

CAUTION

Ensure that all components are coated with

the proper grade of oil as they are assembled.

Failure to follow this caution may result in

damage to engine.

e.

During assembly of internal engine components,

coat all components heavily with oil of the same grade to

be used in the crankcase. During the first few moments of

operation, the engine will depend upon this lubrication.

Refer to Section I of Chapter 3 for proper lubricants.

7-63. Inspection - General

a.

Clean all parts before inspection.

NOTE

If the cylinder block Is cracked, the engine

cannot be overhauled. Be certain to save all

salvageable components.

b.

Use Magnaflux or die penetrating technique to

detect cracks.

c.

Inspect all milled surfaces for pitting, burrs, and

carbon or dirt buildup. Remove all burrs from bolt holes

on machined or milled surfaces.

7-36

Back to Top