TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 399 of 528

TM 9-2330-356-14

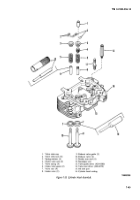

Figure

7-47.

Removing Lower Spring Seat.

TA100118

TA100119

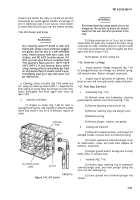

Figure 7-48. Delivety Valve Test Assembly.

NOTE

Always check to ensure that all external

connections are tight and that the nozzle test

stand is in good order.

(b)

Attach test fixture TSE

manually operated Nozzle Test Stand.

76226 (3) to a

(c)

Delivery valve opening pressure is

300-600 psi. Delivery valve must hold 275 psi for 30

seconds. Remove delivery valve assembly from test

fixture. The delivery valve spring (1) must be free of nicks

or wear (flat spots). Replace fuel injection pump if springs

are nicked or worn.

CAUTION

Lapping compound must not come in contact

with the relief piston during the lapping

operation, and all lapping compound must be

removed before installing the delivery valve

assembly into the hydraulic head.

(d)

If the delivery valve assembly is leaky,

the delivery valve seat may be lapped to its corresponding

seat in the delivery valve body with a small quantity of

suitable lapping compound.

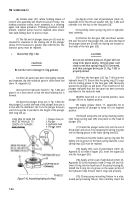

(2) If the plunger bottom (23, fig. 7-46) is

grooved, ridged, scored, or exhibits an uneven wear

pattern, it must be replaced.

(3) Inspect the tappet (20) for possible wear at

the contact areas. The primary contact areas are the

tappet contact area and the cam contact area (fig. 7-49).

Replace the tappet if wear indentations exceed

0.002-inch. The tappet thickness measured between the

plunger button contact surface and the cam contact area

must be 0.207-inch or larger.

TA100120

Figure 7-49. Inspecting Tappet

(4) The pump housing (6, fig. 7-46) should be

washed in a cleaning solvent. Check all the screw threads

in the housing; damaged threads can be repaired using

thread inserts:

(5) Examine the pump housing for cracks or

other damage which will cause oil leakage. Replace

complete pump if pump housing is damaged.

7-43

Back to Top