TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 406 of 528

TM 9-2330-356-14

(d)

Repair minor damage to the cylinder

head castings using a fine file, emery cloth, or crocus cloth

(item 4, Appendix E) dipped in dry cleaning solvent

(item 11, Appendix E). Repair minor damage to threads

using a proper size tap. Do not enlarge the threaded hole.

If minor damage cannot be repaired, replace cylinder head

casting (16) and valve seats (7). Salvage all other usable

components.

(e)

Inspect studs (11) for stripped or worn

threads, or a bent or loose connection. Replace studs if

damaged, using anti-seize compound (item 5, Appen-

dix E). Tighten rocker arm studs to 35-40 lb.-ft.

tool. Allow valve guide to remain 0.3437-inch from top of

cylinder head.

(d)

Ream the replacement valve guide, if

necessary, to obtain proper valve stem-to-valve guide

clearances shown in table 7-2.

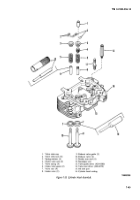

(e) Inspect valve (8 and 10, fig. 7-55) for

warped stem, pitting, evidence of burning and excessive

wear. Replace valves if badly damaged or if valve stem is

worn beyond tolerances shown in table 7-2.

CAUTION

(2)

Valve Guide and Valve.

(a)

Check for valve stem-to-valve guide

allowable clearance by measuring inside diameter of valve

guide (6 and 9, fig. 7-55) and outside diameter of the valve

stem. Refer to table 7-2 for correct dimensions.

NOTE

If valve stem Is worn below minimum toler-

ances, replace the valve. If new valve fails to

correct stem-to-valve guide clearance, re-

place valve guide.

(b)

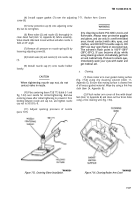

Using Correct size valve guide driver tool

(table 5-1 and 13, fig. 7-55), remove the valve guide.

(c)

Install new replacement valve guide

through top of cylinder head using the valve guide driver

If grinding on valve face produces a valve

with a thin edge, replace with a new valve.

(f)

Repair valves that can be refaced

grinding to the requirements shown in figure 7-56.

(3)

Valve Seat.

(a)

Inspect valve seats. Reface valve seats if

seat face is slightly pitted, burned, or worn and can be

refaced to requirements in figure 7-56. If valve seats are

loose, they must be replaced as follows:

(b)

Secure valve seat remover cutter tool

(fig. 7-57) in a drill press chuck and adjust tool to cut

1/64-inch from outside edge of valve seat.

(c)

Apply oil to pilot end of cutting tool to

prevent seizing in the valve guide (fig. 7-55).

Figure

7-56.

Valve Face and Valve Seat Grinding Requirements.

7-50

Back to Top