TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 402 of 528

TM 9-2330-356-14

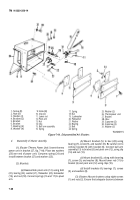

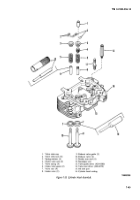

(2) Should nozzle be removed, replace nozzle

cap (1) onto nozzle holder (4) loosely to protect lapped

surfaces of nozzle holder.

(3) Remove plug (5) from protective cap (6).

(4) Unscrew protective cap (6) from adjusting

screw (8). Remove copper gasket (7).

(5) Unscrew adjusting screw (8) from nozzle

holder (4). Be careful-adjusting screw is under spring

pressure.

(6) Remove spring (9) and nozzle spindle (10).

b.

Cleaning.

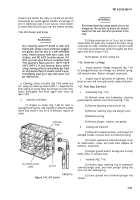

(1) Clean fuel injector parts in a clean room on a

clean bench. Provide a pan of clean diesel fuel (item 14,

Appendix E) and a supply of lint-free cloths (item 24,

Appendix E).

(2) Never use hard or sharp tools, emery paper,

grinding powder, or abrasives of any kind.

(3) If necessary, clean outer surfaces of nozzle

cap with a brass brush, but do not attempt to scrape carbon

from nozzle surfaces because severe damage to spring

hole can result.

(4) Use a soft, oil-soaked cloth to clean nozzle

valve. Clean interior of nozzle cap nut.

c.

Inspection.

Inspect tappet surfaces of nozzle

holder for nicks or roughening. If damaged, replace nozzle

holder.

d.

Repair.

If cleaning will not eliminate an injector

defect, replace injector.

e.

Assembly (Fig. 7-52).

(1) Secure nozzle holder in a suitable holding

fixture.

(2) Install nozzle spindle (10) into nozzle holder

(4).

(3) Install spring

(9)

into nozzle holder and then

screw adjusting screw (8) into nozzle holder. Do not

tighten.

Figure 7-52. Disassembled Fuel Injector

7-46

Back to Top