TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 404 of 528

TM 9-2330-356-14

WARNING

Particles blown by compressed air can be

dangerous. Be certain to direct air stream

away from the user and other personnel In the

area.

(3) Dry oil inlet using clean, filtered, compressed

air under moderate pressure of approximately 15 psi.

b.

Inspection and Repair.

(1) Visually inspect rocker arm cover for nicks or

dents on the gasket mating surface. Inspect cover for

cracks, particularly around the area of the lifting bracket

bolt hole. Inspect bolt holes for damaged or excessively

worn threads, Replace rocker arm cover assembly if

damaged.

(2) Inspect oil line for deep nicks or dents that

may obstruct oil flow. Inspect line for cracks or punctures.

Replace oil line if defective.

7-72. Cylinder Head

unless inspection shows that they are

defective,

b.

Cleaning.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only In a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point Is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, Immediately get fresh

air and medical help. If solvent contacts eyes,

Immediately wash your eyes with water and

get medical aid.

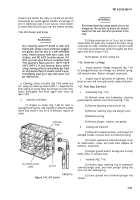

(1) Thoroughly clean all components of the

cylinder head assembly (fig. 7-55) using dry cleaning

solvent (item 11, Appendix E) and a stiff brush.

a.

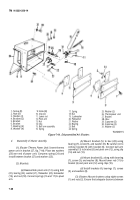

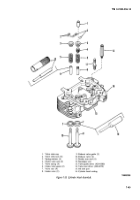

Disassembly (Fig.

7-55).

(2) Check out oil inlet port (15) using a cleaning

(1) Remove valve stem cap (1).

wire, and flush clean with cleaning solvent.

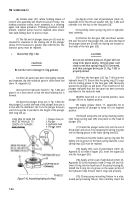

(2) Using a valve spring compressor (fig. 7-55),

depress the valve spring (5, fig. 7-55) and remove both

halves of the valve stem lock (2).

(3) Release valve spring compressor and remove

spring retainer (3), valve spring (5), and valve (8 or 10)

WARNING

Particles blown by compressed air can be

dangerous. Be certain to direct air stream

away from the user and other personnel in the

area.

NOTE

(3) Dry all tapped holes and oil ports using clean,

The seal assemblies with retainers are

dry, compressed air under moderate pressure of 15 psi.

installed on the intake valve guides only.

c.

Inspection and Repair—Cylinder Head Compo-

(4)

Remove seal assemblies (4).

nents.

(5) Repeat steps (1) through (4) to disassemble studs

(1) Cylinder Head Casting and Rocker Arm

remaining intake and exhaust valve components.

(6)

Remove the rocker arm studs (11) only if

(a)

Inspect cylinder head casting (16,

defective.

fig. 7-55) using Magnaflux or die penetrating technique to

detect cracks.

NOTE

(b)

Inspect all finished surfaces for nicks,

Removal procedures for the valve guides (6

scratches, pitting, or excessive wear.

and 9) and the valve seats (7) will be found in

paragraph 7-72c, Inspection and Repair. Do

(c)

Inspect all tapped holes for worn or

not remove the valve guides or valve seats

damaged threads.

7-48

Back to Top