TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 401 of 528

TM 9-2330-356-14

hydraulic head into the pump housing so that the locating

slot in the hydraulic head is in line with the locating screw

hole in the pump housing (not seating).

(16) Install the head locating screw gasket (14) and

the head locating screw (13) into the locating screw hole in

the pump housing (6). Slight repositioning of the hydraulic

head may be necessary to properly install the head

locating screw. Do not use force. Tighten screw (13) to

90-100 lb.-in. Install head retaining clamps (16) and screws

(15). Alternately tighten screws (15) at opposite comers of

housing (6) to properly seat the head assembly (17) in the

housing. Tighten screws (15) to 13-15 lb.-ft. Insert the

timing screw (31) and its gasket (32) into the timing screw

hole in the pump housing. Tighten the timing screw to

20-25 lb.-in.

(17) Install the delivery valve spacer (12), delivery

valve assembly (11), delivery valve spring (10), and delivery

valve holder (9). Tighten delivery valve holder to

70-75 lb.-ft. Install delivery valve cap nut (7) and gasket

(8). Tighten nut to 55-60 lb.-ft.

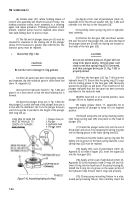

(18) Insert pin (37, fig. 7-46) and flatwasher (38)

into lower hole of lever on control unit assembly (4), and

secure with lockwasher (39) and nut (40). Tighten nut to

20-25 lb.-in.

(19) Ensure that O-ring (33) is seated in control

unit. Apply oil to plunger sleeve pin (5) and insert the

plunger sleeve pin (5) into the control unit assembly (4).

(20) Place pump in horizontal position with

control unit bore (36) facing up.

(21) Center the plunger sleeve (34) in the control

unit bore (36). Position plunger sleeve pin (5) so that the

flats aline with the groove in the control sleeve (34), and

the electric pencil mark (dot) faces the top of the pump.

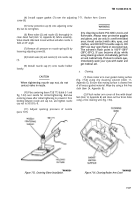

CAUTION

Do not use force. If flange is not seated on

pump housing, rotate arm both ways with

finger pressure pushing control unit in.

NOTE

Rotate the control unit lever (41, fig. 7-46)

through a 360° arc to ensure that the con-

trol unit assembly is correctly installed.

Failure to rotate 360° Indicates that the

plunger sleeve pin (5) is not engaging the

plunger sleeve slot.

If control unit will not seat, pull it out and

repeat steps (20) through (22).

(22) Insert control unit assembly (4) into housing

(6), pressing gently until control unit seats.

(23) Install control unit assembly retaining plate,

as shown in figure 7-51, using two tab washers and two

screws. Tighten screws to 20-25 lb.-in., and bend locking

tabs over screws.

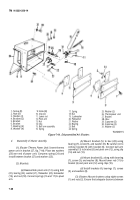

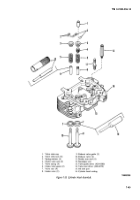

Figure 7-51.

Control Unit Assembly.

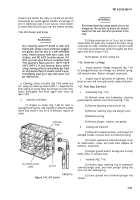

7-70. Fuel Injectors

a.

Disassembly (Fig. 7-52).

CAUTION

Never clamp injector in a vise which has hard-

ened jaws. Damage to Injector would result.

NOTE

When removing and disassembling fuel in-

jectors, separate and label components of

each injector. Never Interchange compo-

nents of injectors.

DO not remove nozzle unless replacement

is required.

(1) Secure fuel injector in a soft-jawed holding

fixture, and remove nozzle cap (1), valve (2), and nozzle

(3).

7-45

Back to Top