TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 396 of 528

TM 9-2330-356-14

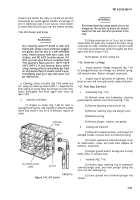

CAUTION

The bottom of the plunger cover must be

sandwiched between the two retainers to

ensure a watertight installation.

(3) Slide the spring, retaining ring, and solenoid

plunger cover over the plunger. Position bottom retaining

ring over the plunger and against bottom of cover.

(4) Secure assembled components with external

retaining ring.

NOTE

During final installation of the fuel stop sole-

noid, the gasket must be installed between

the solenoid retainer and the solenoid.

(5) Connect ground lead to solenoid with screw

and lockwasher.

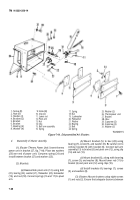

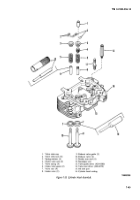

7-68. Oil Filter Adapter

a.

Disassembly (Fig. 7-20).

(1) Remove the two 90° tube elbows (11,

fig. 7-20).

(2)

Remove inverted elbow (10), elbow (15), and

elbow (27).

(3) Remove three screws (21) and lockwashers

(22) securing oil bypass cover (23) to the adapter (19).

Remove the cover.

(4) Remove the spring (25) and thermostat (26).

Discard the thermostat.

(5) Remove and discard the bypass cover gasket

(24).

b.

Cleaning.

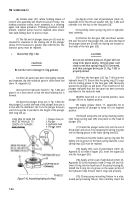

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-590°C). if you become dizzy while

using cleaning solvent, Immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean gasket mating surfaces using dry

cleaning solvent (item 11, Appendix E). Wipe dry using a

clean, lint-free cloth (item 24, Appendix E).

WARNING

Particles blown by compressed air can be

dangerous. Be certain to direct air stream

away from the user and other personnel in the

area.

(2) Flush oil ports and thread holes clean with

diesel fuel (item 14, Appendix E). Air dry ports using

clean, filtered, compressed air under moderate pressure

of approximately 15 psi.

(3) Soak all metal parts in a clean receptacle

containing hydraulic fluid (item 18, Appendix E). Wipe

dry using a clean, lint-free cloth (item 24, Appendix E).

Clean parts with compressed air as in step (2).

(4) Coat all components with oil before

assembly. Refer to Section I, Chapter 3 for the proper

lubricant.

c.

Inspection and Repair.

(1) Visually inspect adapter assembly for nicks or

dents on the gasket mating surfaces. Inspect for cracks.

(2) Inspect threaded holes for damaged or

excessively worn threads. Replace adapter if defective.

d.

Assernbly (Fig.

7-20).

(1) Install spring (25, fig. 7-20) and new

thermostat (26) in the adapter assembly.

(2) Position the cover (23) and new cover gasket

(24) over the thermostat and spring. Secure gasket and

cover to adapter assembly with three screws (21) and

lockwashers (22). Tighten screws securely.

(3) Install inverted elbow (10). Tighten elbow

securely.

(4) Install two elbows (11). Tighten elbows

securely to a position approximately 20° left of top center.

(5) Install elbow (15). Tighten elbow securely to a

position 90° right of top center.

(6) Install elbow (27). Tighten elbow securely to

the position shown in figure 7-20.

7-40

Back to Top