TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 386 of 528

TM 9-2330-356-14

NOTE

DO NOT install crankshaft washer (15) or

retaining ring (14) if camshaft has to be

installed in crankcase. Camshaft gear will not

clear the retaining washer.

Install keys (26 and 27, fig. 7-27) on crankshaft

(37), Use fabricated tool (table 5-2) to drive gear (16) into

place, with beveled side facing engine crankcase. Fully

seat gear. Install crankshaft washer (15) and retaining ring

(14) only if camshaft has not been removed.

l.

Install key (25) on crankshaft. Drive pump

coupling flange (39) onto end of crankshaft. Install washer

(40) and capscrew (41).

m.

n.

o.

p.

q.

r.

s.

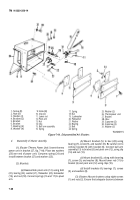

7-39.

a.

Install rod and piston assemblies (para 7-43).

Install oil pump cup assembly (para 7-39).

Install oil base (para 7-43).

Install gear cover assembly (para 7-42).

Install flywheel (para 7-47).

Install cylinder heads (para 7-44).

Install blower housing (para 7-60).

Oil Pump (Fig. 7-32)

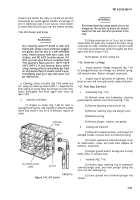

Install gear (7, fig. 7-32), retaining washer (6),

and lock ring (5).

b.

Fill pump intake and outlet with oil to ensure that

it is primed.

CAUTION

Fallure to allow clearance can damage oil

pump.

c.

Mount oil pump (10) on engine using screws (8)

and lockwashers (9). Allow pump drive gear to crankshaft

gear clearance. Clearance must be 0.005-inch backlash.

d.

Install oil cup assembly (1) into oil pump (10).

Install bracket (2) on center main bearing housing

and secure with lockwasher (3) and screw (4).

f.

Install oil base (para 7-43).

g

Install gear cover (para 7-42).

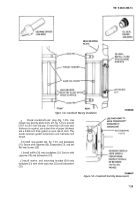

7-40. Camshaft Assembly and Tappets

(Fig. 7-31)

NOTE

Expansion plug must not protrude from rear

face of crankcase.

a.

Press new camshaft bearings into place using

bearing driver 420-0326 (table 5-1). See figure 7-36 for

proper placement. Press bearing flush with bottom of

expansion plug recess. Press front bearing flush with

crankcase front surface with oil passages alined. Do not

attempt to ream bearings; they are a precision type. After

rear bearing is installed, insert a new expansion plug in

recess, using sealing compound, and expand it into place

with sharp blows at its center.

Figure 7-36. Camshaft Bearing Installation.

7-30

Back to Top