TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 384 of 528

TM 9-2330-356-14

Failure to follow this caution may result In

damage to engine components.

e.

During reassembly of internal engine compo-

nents, coat all components heavily with oil of the same

grade to be used in the crankcase. During the first few mo-

ments of operation, the engine will depend upon this lu-

brication. Refer to Section I Chapter 3 for proper

lubricants.

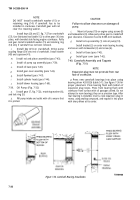

7-38. Crankshaft and Main Bearing Blocks

(fig. 7-27)

After each Installation step, check crankshaft

Figure

7-33.

Cra.nhshaft Gear Removal.

to be sure it is not frozen In place.

o.

Remove bolt (41, fig. 7-27) and washer (40) from

end of crankshaft. Using a puller, remove pump coupling

(39). Remove woodruff key (25).

Remove rear bearing plate (18) from crankcase.

Remove gasket (22) and shims (23).

Remove two bolts (30), washers (31), bottom

center main bearing housing (32), and center bearing (34).

Rotate crankshaft and remove upper center bearing

housing (36) and center bearing (35). Remove crankshaft

(37) through rear opening in crankcase.

7-37. Instruction Procedures

a.

The following paragraphs contain step-by-step

instructions necessary to reassemble the engine following

maintenance procedures.

b.

Prior to undertaking engine reassembly, certain

major components such as the crankshaft, camshaft and

governor, fuel pumps, and cylinder head should be

inspected and repaired as described in Section III, Repair

Instructions.

c.

During reassembly of the engine, the work area

should be as clean as possible to reduce engine

contamination which can cause engine failure.

d.

Use only clean, lint free cloth (item 24, Appen-

dix E) for wiping engine parts. Oil and diesel fuel used

during the reassembly process must be clean. Handle all

parts carefully, especially bearings and machined surfaces.

CAUTION

Ensure that all components are coated with

the proper grade of oil as they are assembled.

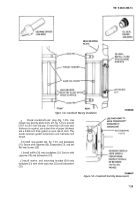

Heat cylinder block (38, fig. 7-27) and bearing

plate (18) at 325°F in oven for 30 minutes, then press front

and rear main bearings (21) into place, alining bearing

housing oil holes (fig. 7-34).

b.

Install thrust washers (24, fig. 7-27) over end of

crankshaft.

Oil the bearings surfaces and install crankshaft

(37, fig. 7-27) from rear of crankcase through rear bearing

plate hole. Aline slots in front thrust washer (24) with

locating pins (fig. 7-34).

d.

Install bearing (34, fig. 7-27) into lower center

main bearing housing (32). Install bearing (35) into upper

center bearing housing (36). Set the upper half of the

center main housing (36) on the crankshaft (37) and rotate

it into place. Be sure it is installed with the side marked

front toward the crankshaft gear. Set the two positioning

dowels (33) on the upper bearing mount. Install the center

main bearing housing (32) and tighten the center main

bolts (30) per specifications in table 7-3.

Place gasket (22) on each side of shim (23) and

place on rear bearing plate (18).

NOTE

Before tightening capscrews(19) ensure that

thrust washers (24) are in position over

locating pins.

f.

Before installing bearing plate, tape keyway and

sharp edges on crankshaft to protect the oil seal during

installation. Place rear thrust washer (24) over locating

pins on rear bearing plate (18). Mount and secure rear

bearing plate (18) with six capscrews (19) and flatwashers

(20).

7-28

Back to Top