TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 388 of 528

TM 9-2330-356-14

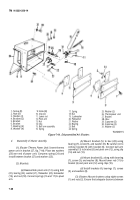

f.

Replace governor arm (3, fig. 7-14) by tightening

screw (3, fig. 7-28).

g.

Install blower housing (para 7-60).

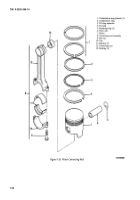

7-43. Pistons and Connecting Rods (Fig. 7-27)

a.

Hone cylinder walls. Clean and oil the cylinder

walls. Install each piston in proper cylinder using a

suitable piston ring compressor. Each piston assembly

should be installed with notch on piston toward front of

engine.

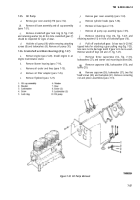

b.

Position each connecting rod on crankshaft, oil

the journal, and install rod cap with bearing half. When

installing rod cap, position so raised witness mark on the

forging matches the mark on connecting rod (figs. 7-27

and 7-39). Piston witness mark should face front, and rod

witness marks toward camshaft side of engine.

CRANKSHAFT

TA100111

a.

Figure

7-39.

Connecting Rod Installation.

c.

Tighten capscrews to specified torque (table 7-3).

NOTE

After installation of new connecting rod or

main bearings,

clearances should be

checked using plastic gage.

d.

turn engine over by hand to see that all bearings

are free.

e.

Install oil base (1, fig. 7-27) with a new gasket (2)

using ten screws (3) and lockwashers (4). Tighten to

specified torque (table 7-3).

f.

Install cylinder heads (para 7-44).

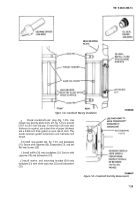

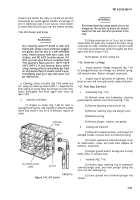

7-44. Cylinder Head and Rocker Arms (Fig. 7-25)

a.

Place head assemblies (8, fig. 7-25) and gaskets

(10) on cylinder block (9). Install springs (18), washers (19),

and seals (16) on push rod shields (17), and install

assembled push rod shields in cylinder block. Lift backside

of cylinder head in place. Use an anti-seize compound

(item 5, Appendix E) on head bolt threads, and thread

bolts (4 and 6) and washers (7) into cylinder block (9). Do

not tighten head bolts at this time.

NOTE

Installing exhaust manifold now alines all four

exhaust ports with exhaust manifold before

the heads are torqued down.

b.

Install exhaust manifold (para 7-52). Tighten

mounting screws to 13–15 Ib.-ft. (table 7-3). Now tighten

head bolts to 44-46 lb.-ft. (table 7-3) following sequence in

figure 7-40.

c.

Install the intake manifold (para 4-82).

d.

Install eight push rods (15, fig. 7-25), rocker arms

(3),rocker arm balls (2), and rocker arm nuts (1).

e.

Set valve clearance (para 7-89).

f.

Replace rocker arm cover and gasket (para 7-45).

g.

Install fuel injectors (para 7-46).

h.

Install the two baffles (34, fig. 7-9), and secure

with capscrew (32) and washer (33).

i.

Install engine shrouding (para 7-60).

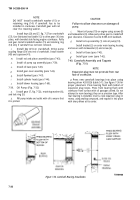

7-45. Rocker Arm Covers (Fig. 7-24)

Place gasket (4, fig. 7-24) in position on each

cylinder head.

b.

Install each rocker arm cover (3) to cylinder head

and secure with four screws (1) and lockwashers (2).

Tighten screws to 8-10 Ib.-ft.

c.

Replace shrouding previously removed

(para 7-60).

7-46.

Fuel Injectors (Fig. 7-23)

a.

Ensure that old gasket material has been

removed from injector (4, fig. 7-23).

b.

Assemble new nozzle gasket (5) adapter (6),

gasket (7), and heat shield (8) on injector (4) and press

together.

c.

Install gasket (9) and injector and assembled parts

into cylinder head (10).

7-32

Back to Top