TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 393 of 528

TM 9-2330-356-14

d.

Inspect all mating surfaces. Be certain that they

are clean and smooth to ensure proper gasket sealing.

7-64. Air Cooling Shrouding

a.

Inspect On Equipment.

(1)

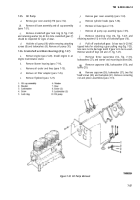

Shutter Assembly.

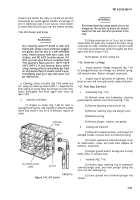

Inspect shutter assembly

(fig. 7-43) for physical damage. Check for debris within

assembly. Check for smooth operation of shutters when

moved manually. Check for chipped paint or rust.

TA502327

Figure 7-43. Shutter Assembly.

(2)

Bracket Assembly.

Inspect that brackets

(fig. 7-43) are securely mounted to shutters. Check that

bracket bearings are not excessively worn.

(3)

Shutters.

Inspect shutters (fig. 7-43) for

physical damage and secure mounting to brackets.

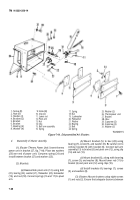

(4) Air Shrouding Door.

Inspect rear cylinder

housing (1, fig. 7-9), top air housing cover (2), air housing

bottom pan (3), and panel door (4) for physical damage.

(5) Grille. Inspect grille (5, fig. 7-9) for secure

mounting to blower housing (6).

(6)

Blower Housing.

Inspect blower housing (6,

fig. 7-9) for physical damage. Check for secure mounting

of blower housing to engine.

b.

Repair.

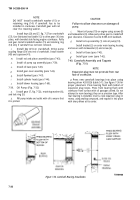

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only In a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point Is 100”F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

Immediately wash your eyes with water and

get medical aid.

(1)

Shutter Assembly.

Refer to paragraph c(1) to

replace defective components. Repair physical damage by

removing dents and welding breaks in shutter assembly

box. Clean repaired area with dry cleaning solvent

(item 11, Appendix E). Paint as required.

(2)

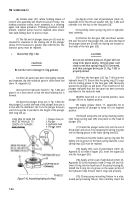

Bracket Assemblies.

Replace bracket (4, 5, and

6, fig. 7-44) or bearings (7) if required.

(3)

Shutters.

Bump out dents and straighten

shutters (3, fig. 7-44) if required. Clean with dry cleaning

solvent (item 11, Appendix E) and repaint if necessary.

(4)

Air Shrouding and Door.

Clean shrouding and

door with dry cleaning solvent (item 11, Appendix E) and

paint if necessary.

(5)

Grille.

Inspect grille (5, fig. 7-9) or secure

mounting to blower housing (6).

(6)

Blower Housing.

Bump out dents in blower

housing (6, fig. 7-9), repair cracks with welds if necessary,

and clean with dry cleaning solvent (item 11,

Appendix E). Paint as required.

c.

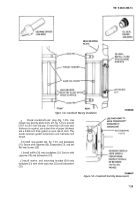

Disassembly of Shutter Assembly (Fig. 7-44).

(1)

Shutters.

Remove eight screws (1, fig. 7-44)

and nuts (2) attaching shutters (3) to bracket assemblies (4,

5, and 6). Remove shutters.

(2)

Brackets.

(a)

Remove brackets (4). Remove bearings

(7) by removing screw (9) and washers (8).

(b)

Remove clips (10) that retain lower rod

(11) in bracket (6) and pivot arm (12). Remove lower rod

and bracket (6). Remove bearing (7) by removing screw(9)

and washer (8).

(c)

Remove nut (13), clip (14), and ball arm

assembly (15). Remove bracket (5) and associated bearing

(7), screw (9), and washer (8).

(d)

Disconnect springs (16 and 17) from

pivot arm (12). Remove pivot arm (12) by removing nut

(18), lockwasher (19), flatwasher (20), washer (21), bearing

(22), and bolt (23).

(3)

Shutter Thermo Power Unit.

Compress spring

(24) and remove washers (25) and thermo power unit (26).

7-37

Back to Top