TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 413 of 528

TM 9-2330-356-14

Immediately wash your eyes with water

and get medical aid.

Particles blown by compressed air can be

dangerous. Be sure to direct air stream

away from the user and other personnel in

the area.

CAUTION

Do not saturate armature or field coils with

solvent as wire Insulation may be dam-

aged. Do not dip drive assembly in solvent

as It Is packed in grease and cannot be re-

placed.

Never use emery cloth to clean commuta-

tor.

(1)

Cleaning.

Clean dust off parts with

compressed air or soft brush. Remove grease and oil with

dry cleaning solvent (item 11, Appendix E). Remove

discoloration or oxidation from commutator with fine

sandpaper grade 00. Clean off sand with compressed air.

Use only sandpaper.

(2)

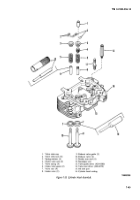

Bearings.

Inspect bearing in pinion housing

for wear. Replace pinion housing (22) if bearing is

excessively worn. Inspect bearing in backplate assembly

(12). If excessively worn, replace backplate assembly.

(3)

Drive Assembly.

Inspect starter drive (29) for

cracks or chipped teeth. Ensure that shaft and spring

under drive moves freely and returns to rear position

when released.

(4)

Brushes.

Lift brush tension springs (14) and

lift each brush (20) from holder for inspection. Check

brush face for deep surface pits, cracks, or chipping.

Measure brush length. When brush is worn to less than

X-inch, replace. Clean the area around brushes and

commutator with dry, low pressure compressed air.

(5)

Solenoid Switch.

Inspect solenoid switch (9)

for cracks, dents, or other damage. Ensure that electrical

terminals are clean and free of corrosion. Check that the

rubber boot on the plunger and yoke is in good condition.

After installation, ensure that plunger and yoke move

freely.

(6)

Armature.

Inspect armature (27) for wear.

Inspect commutator for wear. If worn, replace starter.

(7)

Yoke.

Inspect yoke (26) for damage or wear.

(8)

Frame Assembly.

Inspect frame assembly (19)

for damage. If frame assembly is bad, replace starter.

c.

Assembly.

(1) Slide drive assembly (29) onto shaft of

armature (27). Install stop and lock ring (28) on end of the

armature shaft (27).

(2) Install thrust washer (21) on the end of the

armature shaft (27). Slip yoke (26) onto drive assembly

(29), and install both in pinion housing (22). Install pin (25)

in pinion housing (22) to hold yoke (26) in place.

(3) If brushes (20) are excessively worn, cut brush

leads l-inch from the welded connection (fig. 7-63).

Install new brushes as follows:

(a)

Using rosin core solder and soldering

iron, or heavy duty soldering gun, tin the remaining

sections of the original brush lead.

Figure 7-63. Brush Replacement,

7-57

Back to Top