TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 418 of 528

TM 9-2330-356-14

(17) Attach red and black leads (fig. 7-69) to

regulator (43, fig. 7-64). Attach blue regulator lead to

diode terminal screw by placing the spade terminal under

the head of the screw. Tighten nut on terminal screw

(fig. 7-64). Install regulator, and ensure that the red and

black leads are properly routed through their slots in the

regulator housing (37, fig. 7-64). Install the four screws to

fasten regulator in housing. Remove brush retaining pin

before tightening the screws.

(18) Install diode trio lead and nut.

NOTE

Due to the design of the alternator, a certain

amount of shaft end play will be present in

new or rebuilt units. This end play Is designed

Into the unit and will vary between .004- and

.012-inch.

(19) Install spacer (4), key (11), fan (3), pulley (2),

and nut (1). Tighten nut to 70-80 lb.-ft.

Figure

7-70.

Installing Brush Assemblies.

Section IV. TEST AND ADJUSTMENTS

7-80. General

a.

This section contains the test and adjustment

procedures that are required to be performed on a rebuilt

or repaired engine. These tests must be performed with

engine installed on semitrailer, and with batteries, control

boxes, fuel supply filters, and electrical supply hooked up

to the engine.

WARNING

Carbon monoxide is a colorless, odorless,

and deadly poisonous gas which occurs in

the exhaust fumes of the auxillary power en-

gine. Exposure to air contaminated with car-

bon monoxide produces symptoms of

headache, dizziness, loss of muscular con-

trol, apparent drowsiness, and coma. Perma-

nent brain damage or death can result from

severe exposure to carbon monoxide gas.

b.

Engine must be properly vented to exhaust the

engine to outside air. If possible, avoid sharp bends in

exhaust pipe or use sweeping, large radius elbows. Use a

section of seamless, flexible tubing between the engine

and any rigid pipe to restrict vibration. Increase exhaust

pipe one size larger for each additional 10 feet of length.

c.

For engine operating instructions, refer to

paragraph 2-10.

7-81.

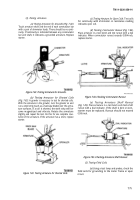

Air Shutter Test and Adjustment

a.

Thermo Power Unit Assembly Test.

Immerse the

thermo unit (26, fig. 7-44) into a container of oil while

monitoring the oil temperature. Plunger of thermo unit

should start to extend when temperature reaches 120°F.

Total extension at 140°F should be at least 13/64-inch.

Replace thermo unit if it does not operate properly.

b.

Adjustments.

(1)

Shutters (Fig. 7-71).

Disconnect ball joint

from upper shutter. Adjust ball joint until upper shutter

closes tightly on lower shutter when lower shutter is held

closed. Reattach ball joint to upper shutter.

7-62

Back to Top