TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 426 of 528

TM 9-2330-356-14

b.

Remove air intake manifold (para 4-82).

7-90. Starter Tests

c.

Remove four fuel injectors (para 7-28).

d.

Insert a compression gage and adapter (table 5-1

and fig. 7-25) into the Number 1 cylinder fuel injector

opening in the cylinder head. Secure the adapter to the

cylinder head with two 5/16-18 NC x 3/4 capscrews.

NOTE

The best indication of compression leakage

is the pressure difference between cylinders.

Compression of a standard new engine

cranking at about 300 rpm is approximately

350-400 psi.

Maintenance should be

considered If pressure is below 325 psi or If

there Is a 15% or more difference between

cylinders.

e.

Turn the engine START switch to the start

position to crank the engine. Record the compression

reading on the gage as the engine is being cranked.

f.

Remove the compression gage and adapter.

Insert adapter in Number 2 cylinder fuel injector opening.

Secure with two capscrews.

g.

Turn the engine START switch to the start

position and crank engine. Record the compression

reading on the gage as the engine is being cranked.

h.

Repeat steps

f

and

g

for Number 3 and Number 4

cylinders.

i.

Install fuel injectors (para 7-46).

j.

Install air intake manifold (para 4-82).

k.

Replace shroud door panel.

a.

On Equipment Test.

Refer to paragraph 4-79 for on

equipment test.

b.

Bench Tests.

(1)

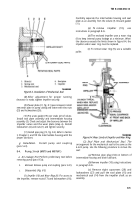

Testing Starter.

(a)

If starting motor tests are required,

remove the motor from the engine and test it on a bench.

Test the free-running voltage and current.

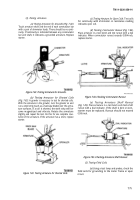

(b)

Using a spring scale and torque arm, test

the stall torque (Fig. 7-81). Multiply the spring scale

reading by the arm length for the torque value.

(c)

If free running speed is low, and starter

has a high current draw with low stall torque, check for

tight, dirty or worn bushings, bent armature shaft, or loose

field pole screws, allowing armature to drag. Check also

for shorted or grounded armature and field.

(d)

A low free speed with low torque and

low current draw indicates an open field winding, high

internal resistance due to poor connections defective

leads, broken or worn brushes, or scored, worn, or dirty

commutator.

(e)

High free speed with low developed

torque and high current draw indicates shorted fields.

Since there is no easy way to detect shorted field coils,

replace and check for improved performance.

(f)

The voltage drop across the solenoid on

the starting motor should be less than 1.5 volts. If not,

remove it for repair.

Figure 7-81. Testing Stall Torque.

7-70

Back to Top