TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 424 of 528

TM 9-2330-356-14

(i)

Check injection port closing point by

repeating steps

(c)

through

(f).

The timing pointer should

indicate the PC mark on flywheel. In no case should

pointer be more than ½ mark away from the P.C. mark.

(j)

Install delivery valve components. Be

sure all parts are clean, and assembled carefully and prop-

erly. The delivery valve holder must be assembled with a

twelve-point wrench, and retightened to 70-80 lb.-ft. The

cap nut must be retightened to 55-60 lb.-ft.

7-87.

Nozzle Assembly Test and Adjustment

The nozzle and holder assemblies are designed to open at

1900-1950 psi. However, after several hundred hours of

operation, the nozzle pressure will decrease to an

acceptable 1750 psi. To test and adjust the nozzle

assemblies, it will be necessary to use a nozzle pressure

tester or pressure gage that reads at least 2000 psi. The

following steps describe test procedures using a pressure

gage.

a.

Remove Number 1 cylinder nozzle and holder

assembly from the engine.

b.

Disconnect fuel inlet line at nozzle and holder

assembly. Attach nozzle inlet line from fuel injection

pump to inlet end of pressure gage.

c.

Attach a flexible line to outlet end of pressure

gage and to inlet end of nozzle. Be certain nozzle-to-fuel

injection return line is attached.

CAUTION

During nozzle test procedures, all nozzles

must be removed from the engine. Failure to

do so may result In damage to the engine.

d.

Remove Number 2, Number 3, and Number 4

cylinder injection nozzles and holder assemblies from

engine, and reconnect fuel inlet and return lines. Use

additional lines and fittings of same gage and material as

required to direct nozzle away from engine.

WARNING

Do not allow nozzle spray to contact skin.

Diesel fuel under pressure can penetrate

flesh and cause serious injury and infection.

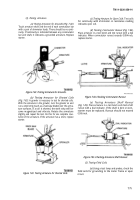

e.

Crank engine and observe pressure gage at

moment fuel is ejected from nozzle. The pressure gage

should read at least 1750 psi opening pressure.

f.

To adjust opening pressure, remove set-screw and

back off adjusting nut cover several turns. Insert allen

wrench through adjusting nut cover and into adjusting

nut. Turn adjusting nut clockwise to increase pressure and

counterclockwise to decrease pressure. Some chattering

of the nozzle is normal during pressure test.

NOTE

If streamers of fuel are visible or the nozzle

drips before It reaches opening pressure of

1750 psi minimum, the nozzle is either dirty or

defective. If dirty, clean nozzle and valve. If

defective, replace nozzle and valve together.

g.

After adjusting nozzle opening pressure,

continue to crank the engine and observe the nozzle spray

pattern. A good spray pattern (fig. 7-79) will be cone

shaped with a solid appearing center surrounded by

cloud-like fog, with the spray evenly atomized.

Figure

7-79. Nozzle

Spray Pattern.

7-68

Back to Top