TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 411 of 528

TM 9-2330-356-14

(2) Install needle bearing (7) and oil seal (6) from

outside of gearcase. Ensure that oil seal is flush with

outside surface of gearcase.

(3) Join the oil seal loader and driver tool (13)

together, and slide the oil seal (11) into position with lip

toward the driver tool. Remove oil seal loader.

(4) Place the gearcase on a firm flat surface and

install the oil seal flush with the gearcase outer surface.

(5) Install the governor shaft (5) and check shaft

for binding.

(6) Install the governor yoke (2) on the shaft with

smooth side toward the governor cup, and secure with

external retaining ring (1).

e.

Test and Adjustment.

(1) Work the governor shaft to check for binding.

(2) Coat all components with oil (para 7-62).

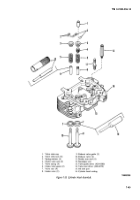

7-76. Governor Cup (Fig. 7-30)

a.

Replace any flyballs that have flat spots or

graves.

b.

Replace cup if race surface is grooved or rough.

The governor cup must be a free spinning fit on camshaft

center pin, but should be replaced if excessively loose or

wobbly.

c.

Check distance the center pin extends from the

camshaft gear. This distance must be 0.781-inch to give

proper travel distance for the cup. If it is less, the engine

may race; if more, the cup will not hold the balls properly.

d.

If

distance is too great, drive or press center pin

in. If it is too small, replace pin; it cannot be removed

without damaging the surface.

e.

If aluminum ball spacer openings are badly worn,

replace ball spacer (camshaft gear must be removed for

this).

Figure 7-61. Crankshaft Peening.

7-77. Crankshaft

(2)

Bearings.

Replace bearings if clearances are

greater than limits (table 7-2), or if bearings are worn,

grooved, or broken.

(3)

Rear Oil Seal.

Inspect seal (17, fig. 7-27) for

wear or damage which might cause it to leak. Use oil seal

driver 420-0250 (table 5-1 and fig. 7-34) to install new seal.

b.

Rebuild Crankshaft.

If

crankshaft requires

regrinding, metallize and regrind to standards. Special

procedures must be observed when reworking diesel

crankshafts. In addition to regrinding, the crankshaft must

be shot-peened and super-finished. Failure to shot-peen

the crankpin fillets is likely to cause early failure. When

the crankshaft is reground, follow this data and figure 7-61

to shot-peen each crankpin fillet.

(1) Peen with 0.019-inch diameter cast steel shot.

(2) Peen for 30 seconds on each crankpin fillet.

(3) Mask off connecting rod bearing arms.

7-78.

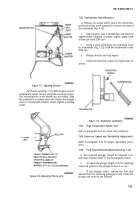

Starter Assembly (Fig. 7-62)

a.

Cleaning and Inspection.

a.

Disassembly.

(1)

Crankshaft.

Clean crankshaft and clear out all

oil passages. Check journals for out-of-round, taper,

grooving, or ridges. Pay particular attention to ridges or

grooves on either side of oil hole areas. Unusual

conditions here often point to previous neglect of oil

changes. If journal dimensions are not within limits or

journals are scored, metallize and regrind crankshaft to

standards (table 7-2).

(1) Remove nut (1) and lockwasher (2) from

solenoid (9). Tag and remove lead (3). Disconnect

connector and grommet

(4).

(2)

Remove cotter pin (5) and pin (6) from yoke

(26). Remove screws (7), lockwashers (8), and remove

solenoid switch (9).

7-55

Back to Top