TM-9-2350-238-20-1 - Page 862 of 1364

TM 9-2350-238-20-1

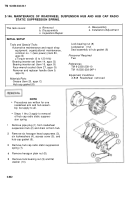

2-145. MAINTENANCE OF ROADWHEEL ARM AND HUB ASSEMBLY AND

ATTACHING PARTS; AND ROADWHEEL PIVOT ARM ASSEMBLY.

This task covers:

a.

Removal/Disassembly

c. Reassembly/Installation

b.

Inspection/Repa\r

INITIAL SETUP

Tools and Special Tools

Automotive maintenance and repair shop

equipment: organizational maintenance,

common no. 1 (less power) (item 80,

appx B)

●

Mechanical puller kit

Hexagon head capscrew (3) (item 23,

appx G)

Hub spacer replacer (item 19, appx G)

Puller adapter (item 2, appx G)

Remover and replacer handle (item 9,

appx G)

Seal guard replacer (item 21, appx G)

Seal inserter (item 11, appx G)

Seal inserter (item 12, appx G)

Slide puller (item 18, appx G)

Sling (item 82, appx B)

Threaded straight pin (2) (item 17, appx G)

Materials/Parts

Bearing ring

Connecting arm sleeve spacer

Cotter pin (2)

Gasket

Grease (item 20, appx

Lockwasher (6)

Plain encased seal

Plain encased seal

Preformed packing

Preformed packing (2)

Roller bearing

Roller bearing (2)

c)

Seal and retainer assembly (2)

Sealing compound (item 37, appx C)

Personnel Required

Two

References

TM 9-2350-238-10

TM 9-2350-238-24P-1

Equipment Conditions

2-848 RoadWheel removed

2-827 Torsion bar removed

2-842 Roadwheel suspension hub

removed

1

2

3

4

NOTE

Procedures are written for one road-

wheel arm and hub assembly but

apply to all roadwheel arm and hub

assemblies.

Remove six hexagon head capscrews (1)

and six Iockwashers (2).

Refer to page 2-831 to gain access to

lock-out cylinder assembly (3) connected

to roadwheel pivot arm assembly being

removed.

Remove two cotter pins (4).

Rig a sling to support lockout cylinder

assembly (3).

2-836

Back to Top