TM-9-2350-256-10 - Page 556 of 796

Table 1.

Operator Preventive Maintenance Checks and Services (PMCS) – After - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

23

AFTER

Track Assembly

1. Check for missing, bent, cracked, or broken track

pins.

One or more missing,

cracked, or broken track

pins.

2. Check for exposed binocular or cooling tubes on

roadwheel path or grouser surface.

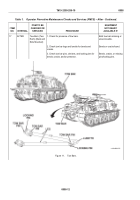

Binocular tubes or cooling

tubes are exposed or

damaged on roadwheel

path and/or grouser

surface. Tube has moved

in or out 0.25 in.

(6.35 mm).

3. Check for dead track shoes. A dead track shoe

appears to be out-of-line.

Any dead track shoes.

4. Check for bent, cracked, and broken center guides

and end connectors.

Any two consecutive

bent, cracked, broken, or

missing center guides.

Any cracked, broken, or

missing end connectors.

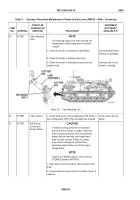

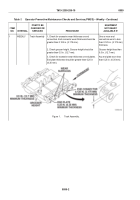

Figure 16.

Track Block Inspection.

TM 9-2350-256-10

0098

0098-18

Back to Top