TM-9-2350-311-20-2 - Page 290 of 828

TM 9–2350–311–20–2

5–34

Change 2

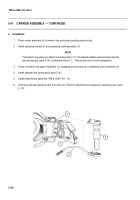

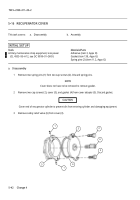

5–12 OPERATING CAM — CONTINUED

b.

Vertical Adjustment

1

Measure clearance of roller (11) from top of cam path. Clearance must be between 3/16 inch (4.8 mm) and

1/4 inch (6.35 mm). Refer to steps 2 and 3 to adjust.

2

Loosen self-locking nut (14).

3

Adjust cradle cam stop (15) with wrench. Turn counterclockwise to increase clearance, clockwise to de-

crease clearance. When adjusted, hold cradle cam stop steady with wrench and tighten self-locking nut (14).

11

15

14

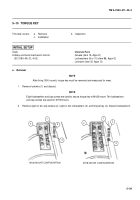

c.

Horizontal Adjustment

1

Rotate crank (16) counterclockwise as far as it will go.

2

Use thickness gage to measure clearance between roller (11) and cam path. Measure at arrow (12). Clear-

ance should be at least 0.001 inch (0.025 mm), but not more than 0.002 inch (0.05 mm). Refer to steps 3

and 4 to adjust.

3

Loosen self-locking nut (16.1).

4

Adjust breech cam pin (17) with wrench. Turn counterclockwise to increase clearance, clockwise to de-

crease clearance. When adjusted, hold breech cam pin steady with wrench and tighten self-locking nut

(16.1).

16.1

16

11

17

12

Back to Top