TM-9-2350-311-20-2 - Page 286 of 828

TM 9–2350–311–20–2

5–30

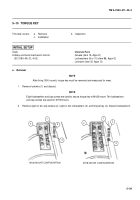

5–10 TORQUE KEY — CONTINUED

b.

Inspection

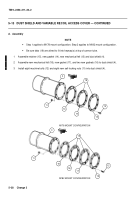

To inspect torque key (4), measure width of bottom surface in at least three different places. Replace torque

key on M185 cannon assembly if width is less than 31/32 inch (24.6 mm) at any point along bottom of taper

or if torque key on M284 cannon assembly is less than 1–9/16 inches (3.97 cm).

c.

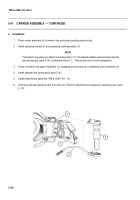

Installation

CAUTION

Do not hammer torque key into keyway(s), as damage to torque key may result. If torque key does

not slide into place, rotate cannon tube slightly by placing a timber or crowbar through the muzzle

brake.

1

Lubricate surfaces of torque key (4) with grease (para 2–9).

2

Install torque key (4), eight or ten new lockwashers (3), and eight or ten cap screws (2).

3

Install new lockwire (1).

4

Check breech operating cam for proper adjustment (para 5–12).

M178 MOUNT CONFIGURATION

M182 MOUNT CONFIGURATION

31/32 inch (24.6 mm)

1–9/16 inches (3.97 cm)

4

4

M178 MOUNT CONFIGURATION

2

3

4

1

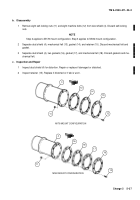

M182 MOUNT CONFIGURATION

1

4

2

3

Back to Top