TM-9-2815-205-24 - Page 692 of 856

INSTALLATION

CAUTION

Cylinder block bore grooves must be clean. Debris in grooves will cause coolant leakage

into engine oil and engine damage can result.

NOTE

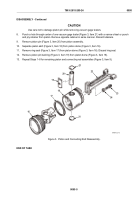

If any pistons and liners are already in engine, use cylinder liner hold-down clamp

(Figure 15, Item 2) to retain liners (Figure 15, Item 1) in place when rotating crankshaft.

1.

Install two new preformed packings (Figure 15, Item 25) in cylinder block bore grooves.

2.

Apply shortening compound or antifreeze to inner surface of new preformed packings (Figure 15, Item 25).

3.

Rotate crankshaft (Figure 15, Item 3) until connecting rod journal of cylinder is at bottom of its travel. Wipe

journal clean and lubricate with clean engine oil.

NOTE

Tang on bearing shell must fit in indentation on connecting rod.

4.

Install upper bearing shell (Figure 15, Item 26) (without continuous oil groove) in connecting rod

(Figure 15, Item 8). Lubricate bearing shell with clean engine oil.

1

2

3

8

25

26

MAINT_367

Figure 15.

Piston Liner Installation.

TM 9-2815-205-24

0094

0094-18

Back to Top